OEM Factory for Thread Rolling Machine - Galvanized Steel Downpipe Roll Former – Yingyee

Short Description:

OEM Factory for Thread Rolling Machine - Galvanized Steel Downpipe Roll Former – Yingyee Detail:

Basic Info

Delivery Time:30 Days

Warranty:12 Months

Material Of Cutting Blade:Cr12

Forming Speed:25-30m/min

Material:GI, PPGI, Aluminum Coils

After Service:Engineers Available To Service Machinery Overseas

Voltage:380V/3Phase/50Hz Or At Your Request

Way Of Driven:Chain Or Gear Box

Type:Pipe Production Line

Cutting Mode:Flying Saw Cutting Or Mould Cutting

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

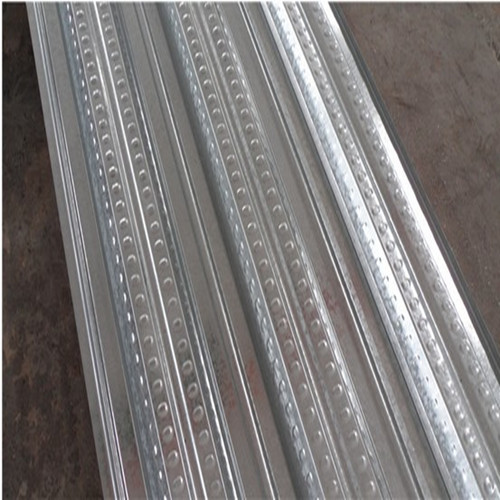

Square Downpipe Roll Forming Machine downspout gutter forming machine

To produce the best aluminum downpipe roll forming machine, YingYee Machinery is taking European quality standard, choose the best material and components, YINGYEE MACHINERY achieves that the machine capacity is double of the competitors, the machine working speed can be 25m/min, and only 1 worker to operate.

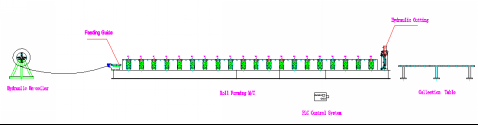

Working Flow: Decoiler – Feeding guide – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting – Output Table

Technical parameters:

| Raw material | PPGI, GI, Aluminum steel |

| Material thickness range | 0.2-0.8mm |

| Rollers | 18 rows |

| Material of forming rollers | 45# steel with chromed |

| Shaft diameter and mateiral | 76mm, material is 40Cr |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Forming speed | 12-15m/min(excluding cutting stoping time) |

| Main motor power | 4 KW |

| Hydraulic station power | 3KW |

| Mode of cutting | Hydraulic cutting or flying saw cutting or mould cutting |

| Control system | PLC Frequency Control System with touch screen |

Pictures of machine:

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal Steel Downspout Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Galvanized Downspout Roll Forming Machine are quality guaranteed. We are China Origin Factory of Downspout Roll Former. If you have any question, please feel free to contact us.

Product Categories : Downpipe Roll Forming Machine > Square Downspipe Roll Forming Machine

Product detail pictures:

Related Product Guide:

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for OEM Factory for Thread Rolling Machine - Galvanized Steel Downpipe Roll Former – Yingyee, The product will supply to all over the world, such as: Turkey, Argentina, Dubai, Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!