Rapid Delivery for Metal Curving Unistrut Roll Forming Machine - Tube Mill line Tube welding line – Yingyee

Short Description:

Rapid Delivery for Metal Curving Unistrut Roll Forming Machine - Tube Mill line Tube welding line – Yingyee Detail:

Basic Info

Model No.:YY–TML—001

Condition:New

Customized:Customized

Theory:Other

Application:Industry

Type:High Frequency Weld Pipe Mill Line

Round Pipe Size Range:Φ8–Φ630 Mm

Round Pipe Thickness Range:0.5-20.0 Mm

Square Pipe Size Range:10*10–500*500 Mm

Squre Pipe Thickness Range:0.5-20.0 Mm

Forming Speed:60-70M/min

Daily Production:6000 Tubes

Additional Info

Packaging:Naked

Productivity:100 SETS/YEAR

Brand:YINGYEE

Transportation:Ocean

Place of Origin:CHINA

Supply Ability:100 SET/YEAR

Certificate:ISO9001

HS Code:84552210

Port:Tianjin

Product Description

Composition

1. Decoiling |

Unrolling the winded skelp. |

2. Butt welding |

Connecting the both ends of skelp for the continuous production. |

3. Accumulator |

Stacking the connected skelp to decrease the material preparation time. |

| 4. Forming | Passing skelp through the roll forming tool. |

| 5. Welding | Welding process by electric resistance. |

| 6. Cooling | Air and water cooling to uniformalize the heated organization after high frequency heat treatment process. |

| 7. Sizing | To accurate the out diameter of pipe. |

| 8. Cut-Off | Cutting to ordered dimension. |

| 9. Straightening | Passing through the correction gap for the straightness. |

| 10. End facing | Chamfering & beveling the cut side according customer`s order. |

| 11. Hydrostatic testing | Checking the water leak and crack. |

| 12. Packing | Packing by ordered. |

MODELS

| MODEL | Round pipe diameter range (mm) | Round pipe thickness range (mm) | Square pipe diameter range (mm) | Square pipe thickness range (mm) | Forming speed (m/min) |

| YY20 | Φ8–Φ20 | 0.5-1.2 | 10*10–20*20 | 0.5-1.0 | 20-100 |

| YY32 | Φ12–Φ32 | 0.6-2.0 | 10*10–25*25 | 0.6-1.8 | 20-100 |

| YY50 | Φ15–Φ50 | 0.8-3.0 | 15*15–40*40 | 0.8-2.5 | 20-80/120 |

| YY63 | Φ21–Φ63 | 0.8-3.5 | 15*15–50*50 | 0.8-3.0 | 20-80/120 |

| YY76 | Φ21–Φ76 | 1.0-4.0 | 20*20–60*60 | 1.0-3.5 | 20-80/120 |

| YY89 | Φ32–Φ89 | 1.5-4.5 | 25*25–70*70 | 1.5-4.0 | 20-70 |

| YY114 | Φ48–Φ114 | 1.5-5.0 | 40*40–90*90 | 1.5-4.5 | 20-60 |

| YY140 | Φ48–Φ140 | 1.5-5.5 | 40*40–110*110 | 1.5-5.0 | 20-60 |

| YY165 | Φ60–Φ165 | 2.0-6.0 | 50*50–130*130 | 2.0-5.5 | 10-45 |

| YY219 | Φ89–Φ219 | 3.0-8.0 | 70*70–180*180 | 3.0-7.0 | 10-35 |

| YY273 | Φ114–Φ273 | 5.0-10.0 | 100*100–200*200 | 4.0-8.0 | 10-35 |

| YY325 | Φ165–Φ325 | 6.0-12.0 | 120*120–250*250 | 6.0-10.0 | 10-30 |

| YY426 | Φ219–Φ426 | 8.0-14.0 | 150*150–300*300 | 8.0-12.0 | 10-30 |

| YY508 | Φ273–Φ508 | 10.0-16.0 | 200*200–400*400 | 10.0-16.0 | 10-20 |

| YY630 | Φ325–Φ630 | 12.0-20.0 | 250*250–500*500 | 12.0-20.0 | 10-20 |

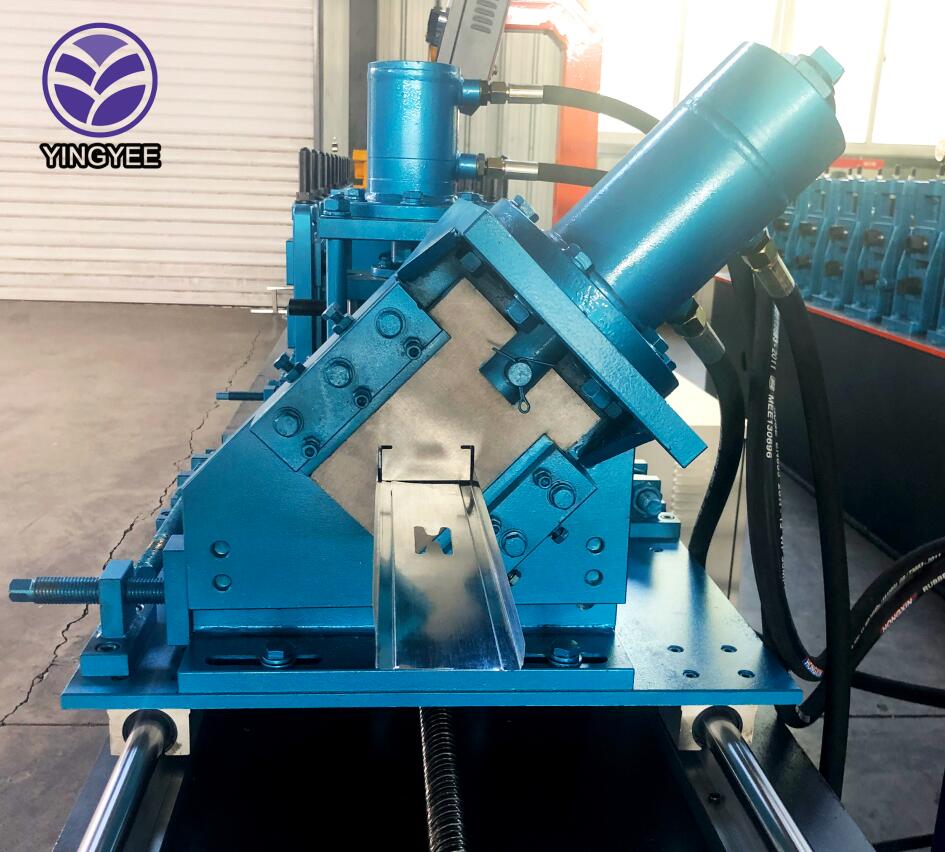

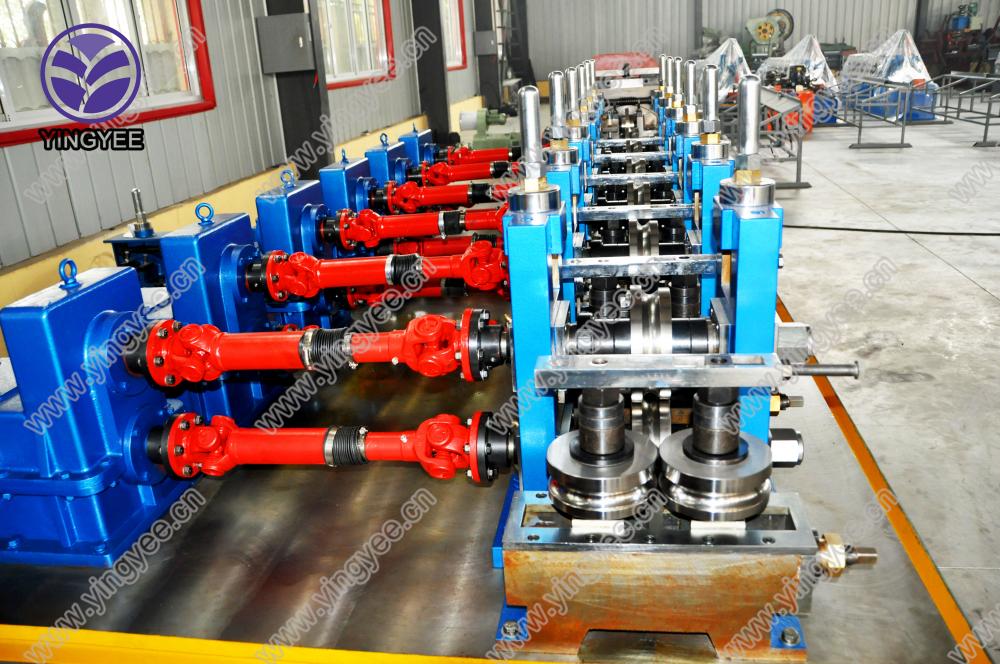

Machine Picture

Looking for ideal High Speed Tube Mill Line Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the High Quality Tube Mill Welding Line are quality guaranteed. We are China Origin Factory of Low Price Tube Mill Line. If you have any question, please feel free to contact us.

Product Categories : Tube Mill Line

Product detail pictures:

Related Product Guide:

Sticking to the belief of "Creating products of high quality and making friends with people from all over the world", we always put the interest of customers in the first place for Rapid Delivery for Metal Curving Unistrut Roll Forming Machine - Tube Mill line Tube welding line – Yingyee, The product will supply to all over the world, such as: Nairobi, Slovakia, Roman, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.