OEM/ODM Factory Steel Square Pipe Making Machine - Angle Iron Roll Forming Machine – Yingyee

Short Description:

OEM/ODM Factory Steel Square Pipe Making Machine - Angle Iron Roll Forming Machine – Yingyee Detail:

Basic Info

Control System:PLC

Delivery Time:30 Days

Warranty:12 Months

Material Of Cutting Blade:Cr12

Type:Steel Frame & Purlin Machine

After Service:Engineers Available To Service Machinery Overseas

Voltage:380V/3Phase/50Hz Or At Your Request

Way Of Driven:Chain Or Gear Box

Forming Speed:30-40m/min(excluding Punching)

Cutting Mode:Servo Tracking Cutting

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

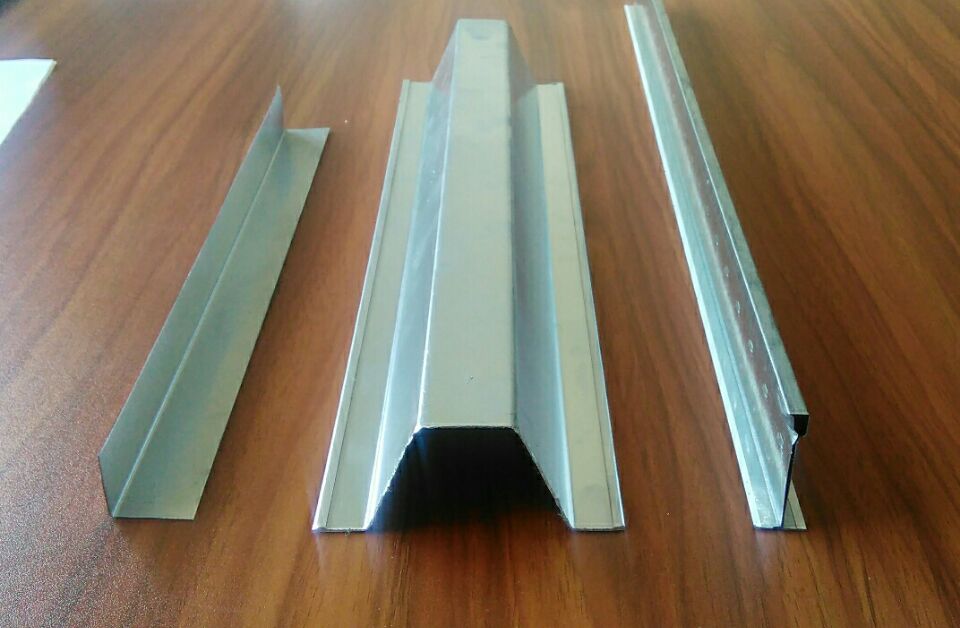

Angle Iron Roll Forming Machine

U purline formed by U purline forming machine,advantages of well compressive strength and flatness; automatioc measureing, cutting and punching; high-level of automation and conveniently installation..

Working process:

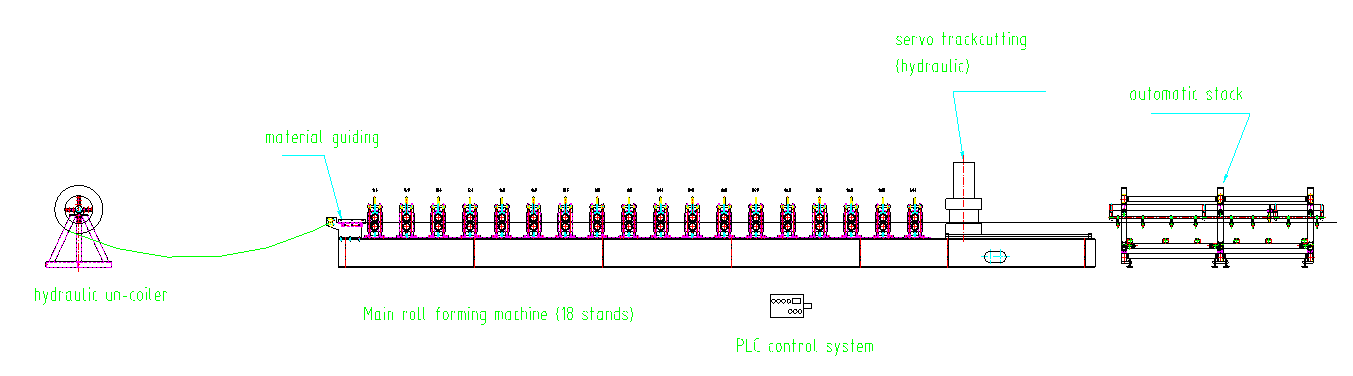

Decoiler – Feeding guide – Straighteing – Main roll forming machine – PLC control system – Servo tracking cutting – Receiving table

Technical parameters:

| Raw material | PPGI, GI, Aluminum coils |

| Material thickness range | 0.3-1mm |

| Forming speed | 30-40m/min(without punching) |

| Rollers | 12 rows |

| Material of forming rollers | 45# steel with chromed |

| Shaft diameter and material | 40mm, material is 40Cr |

| Controlling system | PLC |

| Cutting mode | Servo tracking cutting |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Voltage | 380V/3Phase/50Hz or at your requirement |

| Main motor power | 4KW |

| Hydraulic station power | 3KW |

| Way of driven | Gear box |

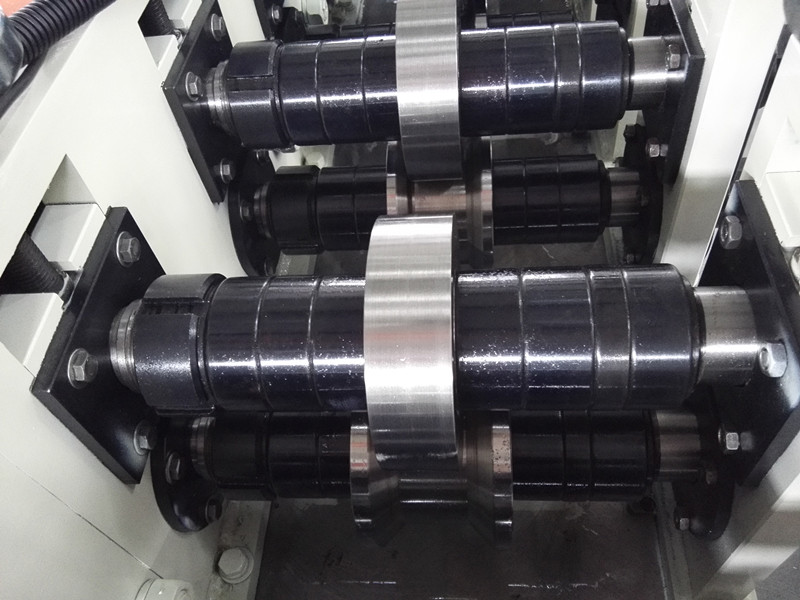

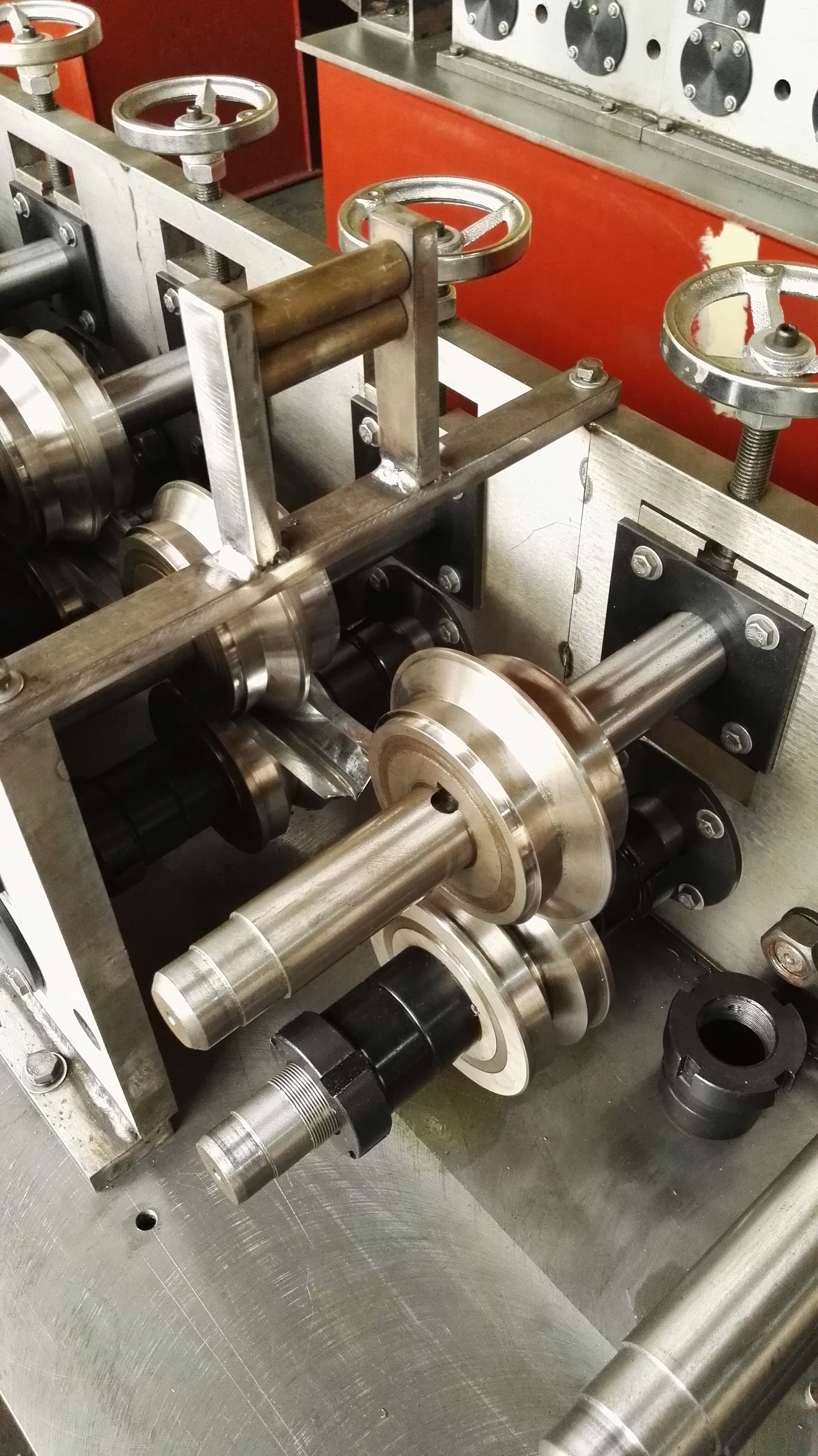

Pictures of machine:

Product detail pictures:

Related Product Guide:

With this motto in mind, we've got become among essentially the most technologically innovative, cost-efficient, and price-competitive manufacturers for OEM/ODM Factory Steel Square Pipe Making Machine - Angle Iron Roll Forming Machine – Yingyee, The product will supply to all over the world, such as: Anguilla, Iran, Hyderabad, With the effort to keep pace with world's trend, we will always endeavor to meet customers' demands. If you want develop any other new products, we can customize them for you. If you feel interest in any of our products or want develop new products, please feel free to contact us. We are looking forward to forming successful business relationship with customers all over the world.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!