Factory Supply Guard Rail Cold Roll Forming Machine - Electronic Equipment Radiator Enclosure forming machine – Yingyee

Short Description:

Factory Supply Guard Rail Cold Roll Forming Machine - Electronic Equipment Radiator Enclosure forming machine – Yingyee Detail:

Parameter:

(1) The maximum passing width of the sheet is 462mm

(2) Feeding method: Servo feeding

(3) Feeding times according to punching times

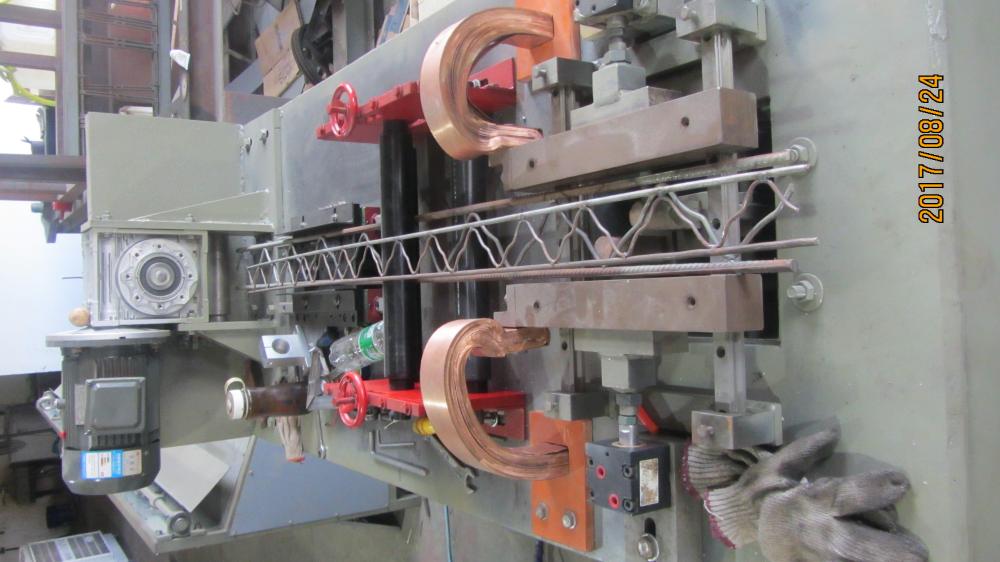

Punching system

1. Composed of 4 hydraulic punching machine

2. Component:Base, hydraulic pressure device, hydraulic system, etc.;

3. Parameter: (1) Rated pressure 16Mpa-25 Mpa

(2) Power 7.5KW

4. Function: Complete the logo and hook/cut angle of 2F board.

Complete the logo and hook/cut blanking of the 1F board to provide a sheet for the single hand plug forming.

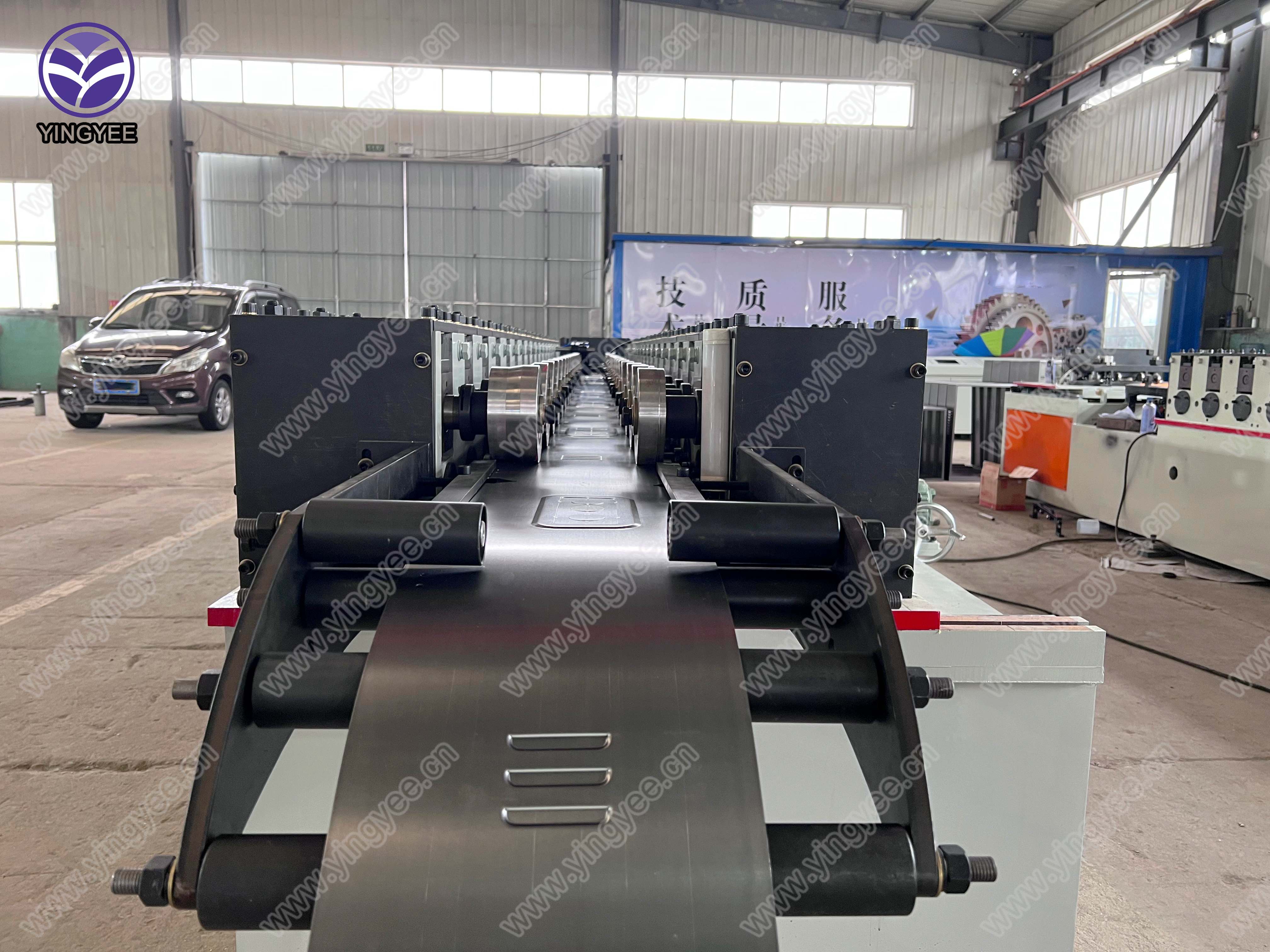

Roll forming machine

Machine 1 for Fundo F2: Torii through shaft

structure + cantilevered host structure; Complete continuous feeding molding.

Machine 2 for Fundo F1: Torii through shaft structure + cantilevered host structure; Complete single-sheet hand plug feeding

forming.

Structure: Quick-change type adjustment mechanism. The bed adopts welded structure and stress relief treatment; the gear adopts 45

steel hard tooth surface;

High strength, high hardness, high precision, high service life.

Parameters:

(1) Raw material thickness 0.6mm (when σs≤260Mpa)

(2) Raw material width ≤462mm (adjustable)

(3) Forming passes: Forming machine ①: 17 passes; Forming machine ②: 12 passes

(4) Motor power 5.5kw, frequency conversion motor

(5) Transmission mode Gear transmission

(6) Rolling mill speed 0-12m/min

(7) Roll material Cr12 quenched HRC56°-60°

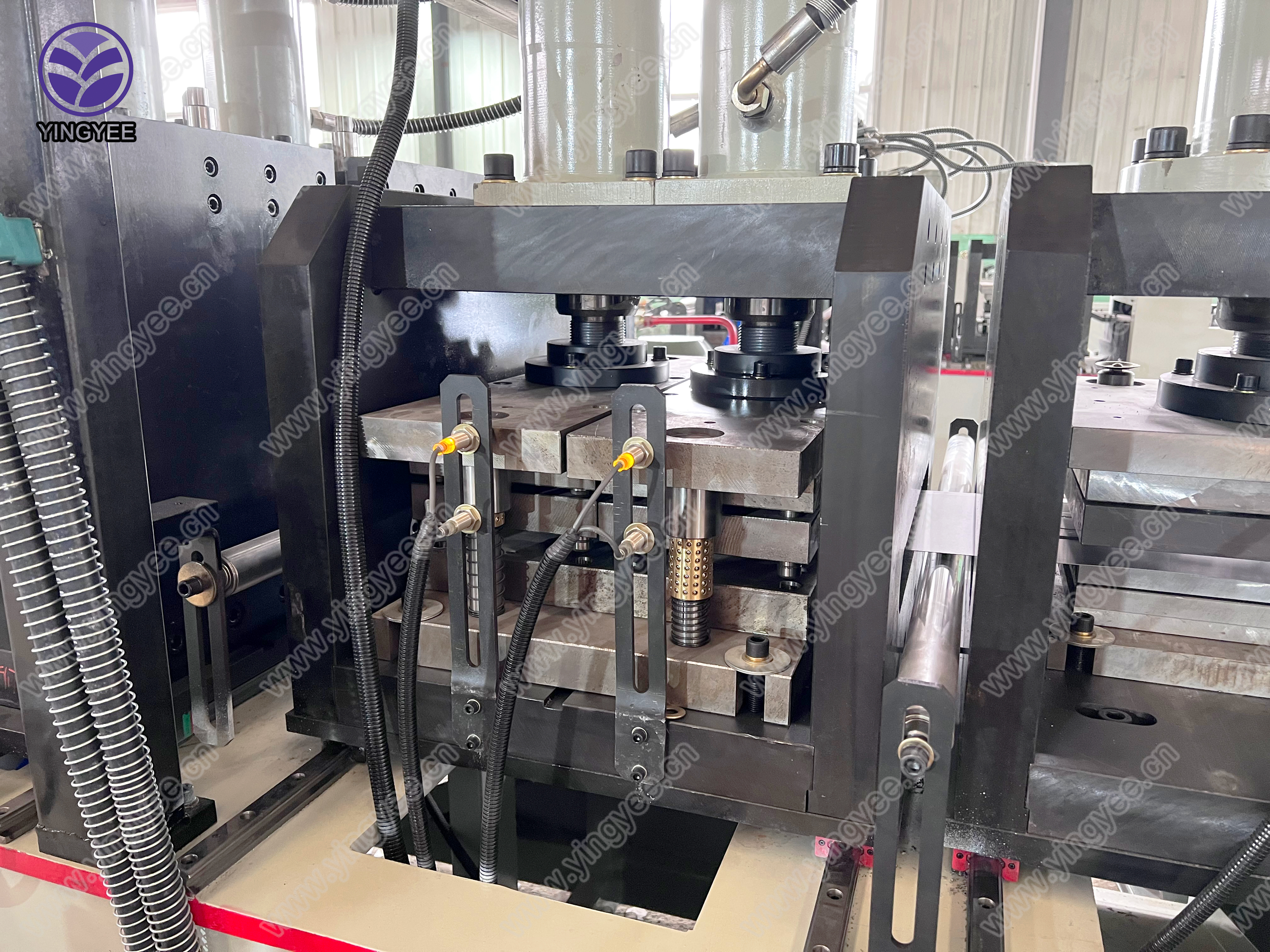

Automatic Hydraulic track cutting machine

Function: Automatically cut and bend the cold-formed profile on-line according to the size requirements.

Stucture:

Cutting head: Cylinder, top plate, column, base plate.

Machine body: Plates, wheels, axles, frame bodies, buffers, base beams, etc.

Parameters:

(1) Maximum cut section (length×width) 433×16mm

(2) Land size (length×width): 1000mm×800mm

(3) Hydraulic power: 4kw

Receiving table

Structure: roller type, no power; composed of bed, support, roller shaft,

Electrical control system

The whole line adopts PLC control, LCD touch

screen, man-machine interface.

Function:

(1) Digital setting of part length.

(2) The length of the parts can be adjusted.

(3) Real-time monitoring of equipment operating status and fault indication.

There are two modes of operation: manual/automatic

In the manual state, it can be operated as a stand-alone machine, which is convenient for maintenance; in the automatic state, the

whole line of production operation is carried out, and the sequence starts

Emergency stop buttons on the whole line, which are easy to handle emergency accidents and ensure the safety of equipment and

operators

Product detail pictures:

Related Product Guide:

Our progress depends about the advanced products ,fantastic talents and continuously strengthened technology forces for Factory Supply Guard Rail Cold Roll Forming Machine - Electronic Equipment Radiator Enclosure forming machine – Yingyee, The product will supply to all over the world, such as: Botswana, Roman, Czech Republic, We are seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.