18 Years Factory Comflor 225 Cold Bending Machine - 0.2-3 mm Cold Rolled Galvanized Steel Coils – Yingyee

Short Description:

18 Years Factory Comflor 225 Cold Bending Machine - 0.2-3 mm Cold Rolled Galvanized Steel Coils – Yingyee Detail:

Basic Info

Model No.:YY–GIC–004

Thickness:0.28 -4 Mm

Width:600-1250 Mm

Znic Coating:40-275 G/㎡

Standard:AISI, ASTM, BS, DIN, GB, JIS

Grade:SGCC,CGCC,SGCD,SPCC,DX51D,DX52D,DX53D

Additional Info

Packaging:EXPORT PACKAGE

Productivity:5000 TONS/MONTH

Brand:YY

Transportation:Ocean

Place of Origin:China

Supply Ability:5000 TONS/MONTH

Certificate:ISO9001

Port:TIANJIN PORT

Product Description

Our 0.2-3 mm Cold Rolled Galvanized Steel Coils (GI Coils) is one of the most popular materials in home and abroad,available in a variety of specifications.

Hot dip galvanizing is the process of applying a zinc coating to Cold rolled steel strip by immersing the material in a bath consisting primarily of molten zinc. The simplicity of the galvanizing process is a distinct advantage over other methods of providing corrosion protection.

Galvanizing forms a metallurgical bond between the zinc and the underlying steel , creating a barrier that is part of the metal itself. 0.2-3 mm Cold Rolled Galvanized Steel Coils (GI Coils) is generally used in Roofing, Refrigerator door & body panels and manufacture of various parts Home appliances.

We can supply different size and thickness of 0.2-3 mm Cold Rolled Galvanized Steel Coils (GI Coils) as your requirement.

Production Process

SGCC galvanized steel coils (GI Coils) and slit coils are also offered as per customer requirement The grade AGIS usually supply is ASTM A 653 in lock forming quality, JIS G3302 SGCC, Structural Grade 50 in regular spangle, cromated, non-skinpassed, unoiled/dry Size:thickness from 0.28 mm to 2.50 mm, in width 1000/1219 or 1250 and slit coils Zinc Coating: Z40 up to Z275 gm/m2 We supply GI Sheets in width 1000/1219 and 1250 and length maximum 6000 mm along with cut to length. We supply minimum/regular spangle coils from our overseas mills and regular spangle coils thicknesses 0.28 mm and up to 4.0 mm.

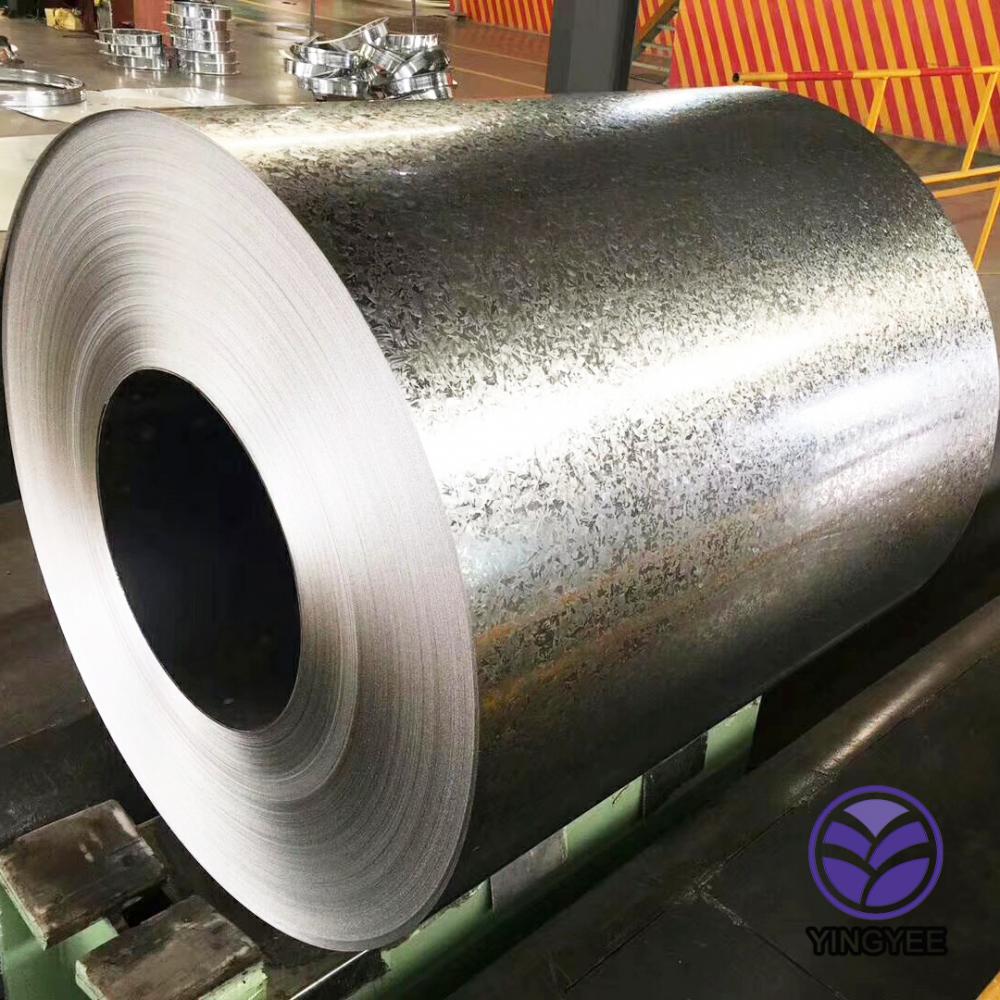

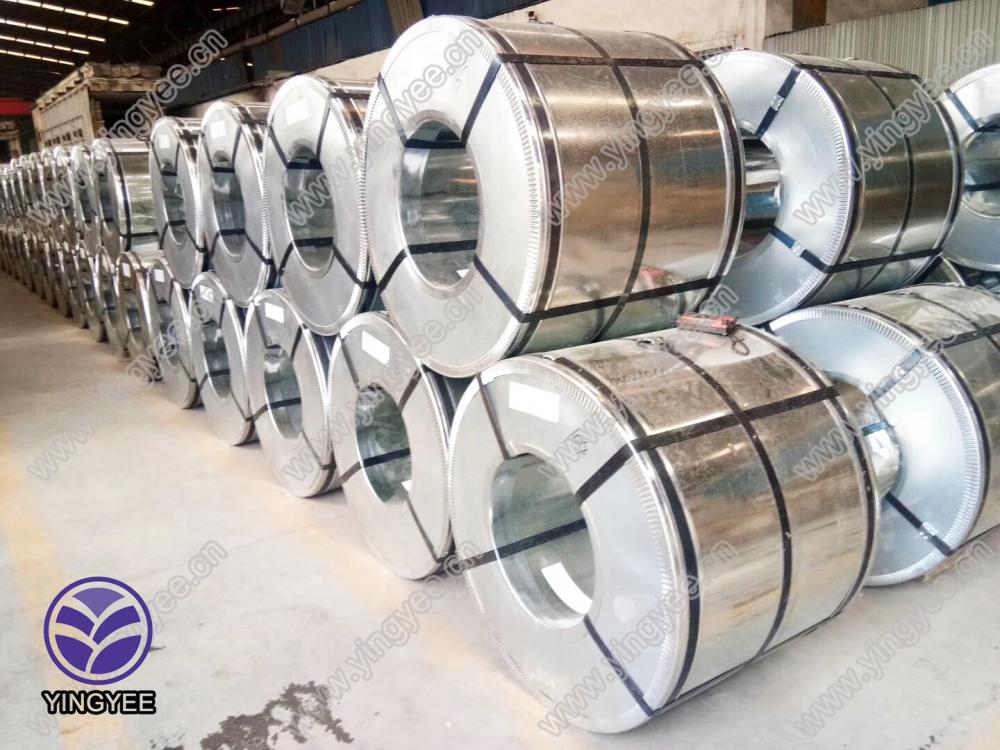

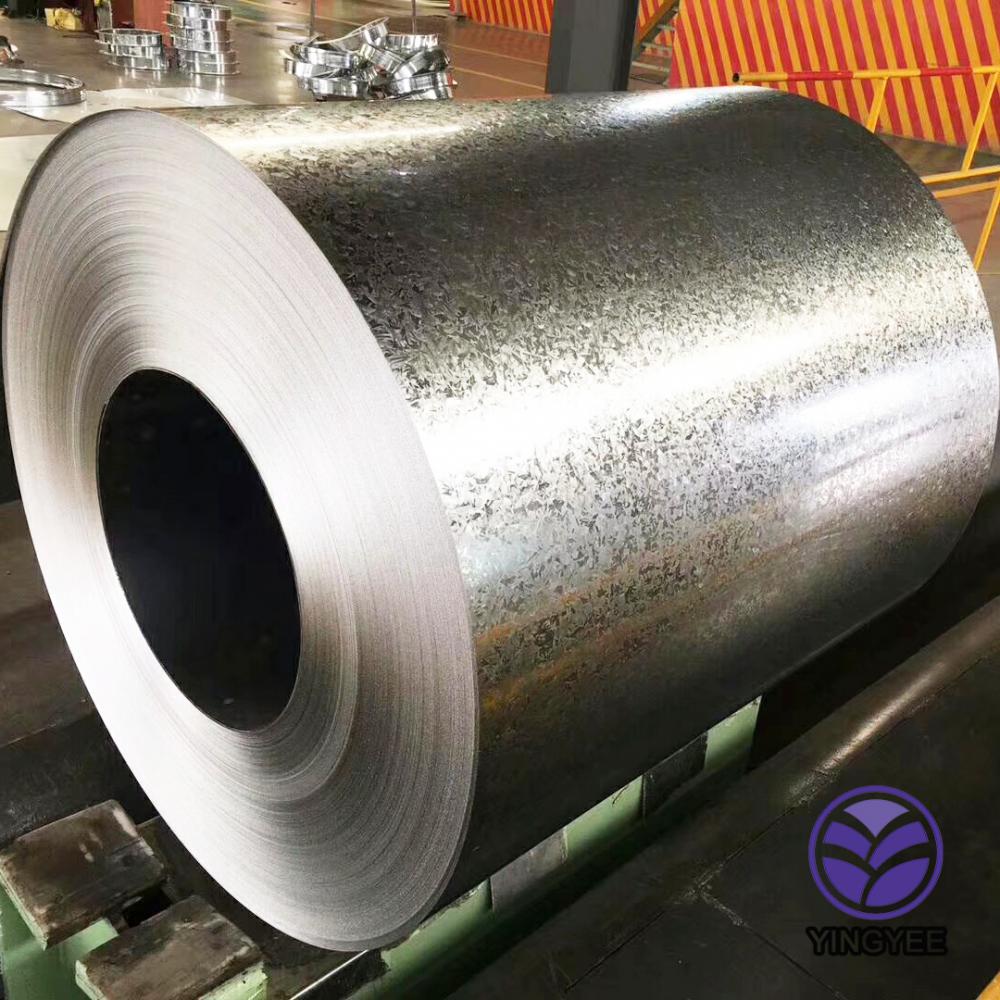

Production Picture

Looking for ideal Lower Price Galvanized Coils Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Cold Rolled GI Coils are quality guaranteed. We are China Origin Factory of 0.2-3 Mm Thicknsss GI Coils. If you have any question, please feel free to contact us.

Product Categories : Galvanised Steel Coils

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for 18 Years Factory Comflor 225 Cold Bending Machine - 0.2-3 mm Cold Rolled Galvanized Steel Coils – Yingyee, The product will supply to all over the world, such as: Uganda, Sevilla, Oman, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!