ibr metal roof sheet cold roll forming machine

Short Description:

Basic Info

Type:Tile Forming Machine

Voltage:38oV/3Phase/50Hz Or At Customer’s Request

Control System:PLC

Warranty:12 Months

Thickness:0.3-1mm

Forming Speed:25-30m/min

Material:GI, PPGI, Aluminum Coils

Cutting Mode:Hydraulic

Delivery:30 Days

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin Xingang

Product Description

Trapezoid Roof Sheet Forming Machine

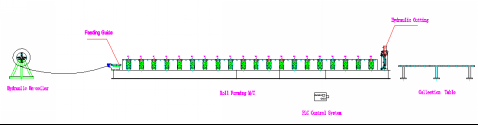

IBR metal roof sheet Cold Roll Forming Machine line includes 7 tons manual decoiler, roll forming host, PLC control system and hydraulic cutting system.

The manual decoiler is free for the machine, it can hold 7 tons of raw material, and normally the distance between the manual decoiler and the roll forming host is 3 meters.

Roll forming host has 11 rows of rollers to make profiles as per customer’s request.

Roll forming machines metal roofing , Metal galvanized coils as raw material, PLC control, Chain transmission, has fast speed,feature of high stabilization

Working Flow: Decoiler – Feeding Guide – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting – Output Table

Technical parameters:

| Raw materials | Galvanized coils, Pre-painted coils, Aluminum coils |

| Material thickness range | 0.2-1mm |

| Forming speed | 10-15m/min |

| Rollers | 15 rows(according to drawings) |

| Material of rollers | 45# steel with chromed |

| Shaft material and diameter | 76mm, material is 40Cr |

| Material of body | 400H steel |

| Wall panel | 20mm Q195 steel(all with electrostatic spraying) |

| Controlling system | PLC |

| Main power | 5.5KW |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Voltage | 380V/3Phase/50Hz |

| Total weight | about 4 tons |

Pictures of machine: