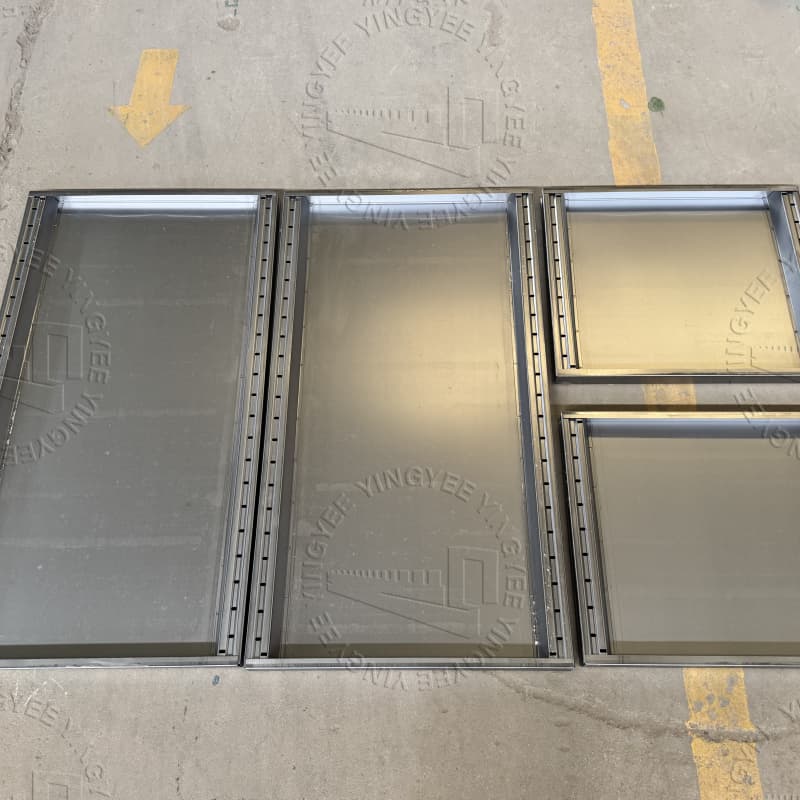

Seamless Production of Shelf Panels with Advanced Roll Forming Technology

Short Description:

- The main technical standards followed

1.1 GB/T6725-2002 “Technical Specifications for Cold-Formed Thin-walled Steel”

1.2 GB/T6728-200 “Dimensions, appearance, weight and allowable deviation of cold-formed hollow steel for structures”

1.3 GB6723-86 “General cold-formed open section steel size, shape, weight and allowable deviation”

1.4 GB/709-88 “Dimensions, shapes, weights and allowable deviations of hot-rolled steel sheets and strips”

1.5 GB/708-88 “Dimensions, shapes, weights and allowable deviations of cold-rolled steel sheets and strips” - Basic production conditions of equipment

2. Equipment production conditions:

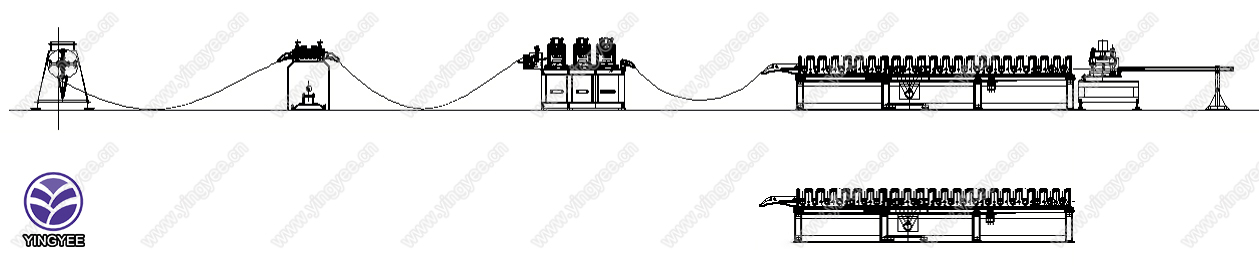

2.1 The equipment covers an area: 30×3×2 (length×width×height) meters.

2.2 Equipment feeding direction: left in and right out.

2.3 Voltage parameter 380, 50Hz, 3 phases.

2.4 Air source: the flow rate is 0.5m³/Min; the pressure is 0.7MPa.

2.5 Hydraulic oil: 46# hydraulic oil.

2.6 Gear oil: 18# hyperbolic gear oil. - Main technical parameters of the equipment

3.2.1 Rolled strip width: ≤775mm

3.2.2 Rolled strip thickness: 0.6mm/0.9mm

3.2.3 Rolled strip material: cold-rolled steel strip yield limit σs≤260Mpa

3.2.4 Roll material: Cr12, quenched HRC56°-60°

3.2.5 Molding speed: 0~12m/min, online speed 0-6 M/min

3.2.6 Rolled workpiece length: user free setting

3.2.8 Total installed capacity of equipment: about 30KW. - Processing

Send your message to us:

Write your message here and send it to us

2-300x300.jpg)