OEM/ODM Factory Steel Square Pipe Making Machine - Long Span Roofing Sheet Production Line – Yingyee

Short Description:

OEM/ODM Factory Steel Square Pipe Making Machine - Long Span Roofing Sheet Production Line – Yingyee Detail:

Basic Info

Model No.:yingyee007

Tile Type:Colored Steel

Certification:CE, ISO

Condition:New

Customized:Customized

Usage:Roof, Wall

Transmission Method:Machinery

Products:Big Span Roll Forming Machine

Material:Pre-printed Steel Coil,galvanized Coil,Aluminum Co

Material Of The Cutting Blade:CR12

Speed:10-25m/min

Cutting Mode:Hydraulic

Control Mode:PLC

Voltage:As Customers Request

Additional Info

Packaging:NUDE

Productivity:CHINA

Brand:YY

Transportation:Ocean,Land,Air

Place of Origin:Hebei

Supply Ability:200sets/years

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin,Shanghai,Qingdao

Product Description

Long Span Roofing Sheet Production Line

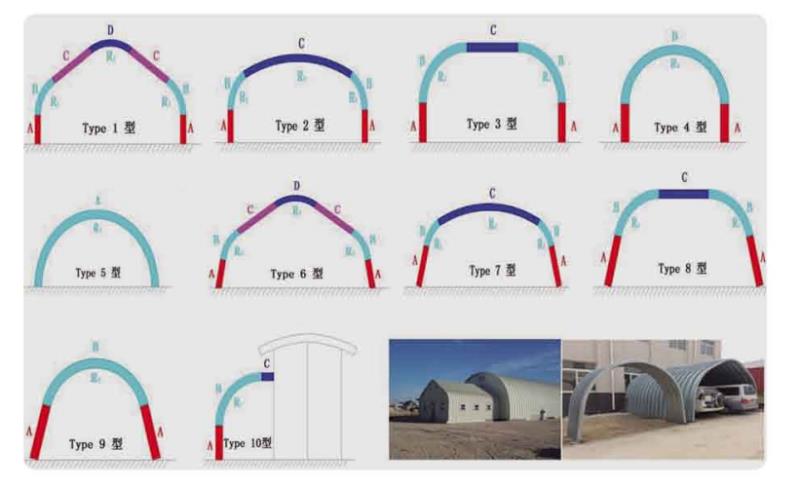

Our Long Span Roofing Sheet Production Line is developed by ourselves with technology same as Roof Cold big span roll forming machine from advanced industries, America. Our machine adopts simple structure, electric driven, simpler operation and more convenient maintenance. Our Long Span Roofing Sheet Production Line is comprised of mechanical expansion decoiler, straight panel forming unit, motorized model cutting device, curving unit, control system, run-out racks for straight and curve panels and all other accessories and tools. All parts are installed on a mobile chassis. So it is suitable for site working.

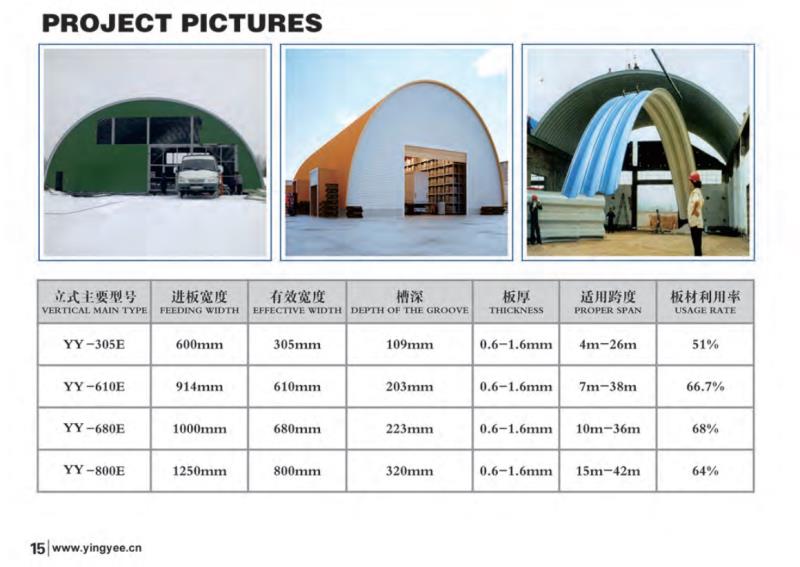

Specification:

1) Main machine dimension: 9.65m*2.23m*2.4m

2) Bending machine dimension; 3.8m*2.23m*2.4m

3) Suitable material: galvanized steel, colored steel, etc

4) Coil thickness: 0.6 –1.5mm

5) Roller stands:16

6) Roller diameter:80mm

7) Totally power:18.5kw

8) Main Power:7.5kw; Hydraulic power:4.0kw; side bending power:1.5kw*2

Curving power:4.0kw

9) Roller material: 40Cr

10) Shaft material: high grade #45 steel

11) Cutting Blade material:Cr12 steel

12) Machine speed: forming speed 13m/min, Seaming speed:6m/min

13) Span : ≤38m

14) Power supply: AC380V±10%, 50Hz, or as per your requirement

Main product :

- Roof roll forming machine

- Roller Shutter Door Roll Forming Machine

- C and Z purlin roll forming machine

- Downpipe Roll Forming Machine

- Light Keel Roll Forming Machine

- Guardrail Roll Forming Machine

- Storage roll forming machine

- Cable Tray Roll Forming Machine

- Shearing Machine

- Hydraulic decoiler

- Bending machine

- slitting machine

Installation and training:

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation. Certification and after service

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period.

2. Effective communication

3. Interface customized.

Looking for ideal Long Span Curving Roof Building Machinery Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Roof Span Curving Machine are quality guaranteed. We are China Origin Factory of Color Metal Large Span Making Machine. If you have any question, please feel free to contact us.

Product Categories : Long Span Roll Forming Machine

Product detail pictures:

Related Product Guide:

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for OEM/ODM Factory Steel Square Pipe Making Machine - Long Span Roofing Sheet Production Line – Yingyee, The product will supply to all over the world, such as: Qatar, Houston, Pakistan, We are your reliable partner in international markets with the best quality products. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.