Newly Arrival Gutter Cold Roll Forming Machine - Color sheel sheet Shearing Machine – Yingyee

Short Description:

Newly Arrival Gutter Cold Roll Forming Machine - Color sheel sheet Shearing Machine – Yingyee Detail:

Basic Info

Warranty:12 Months

Delivery Time:30 Days

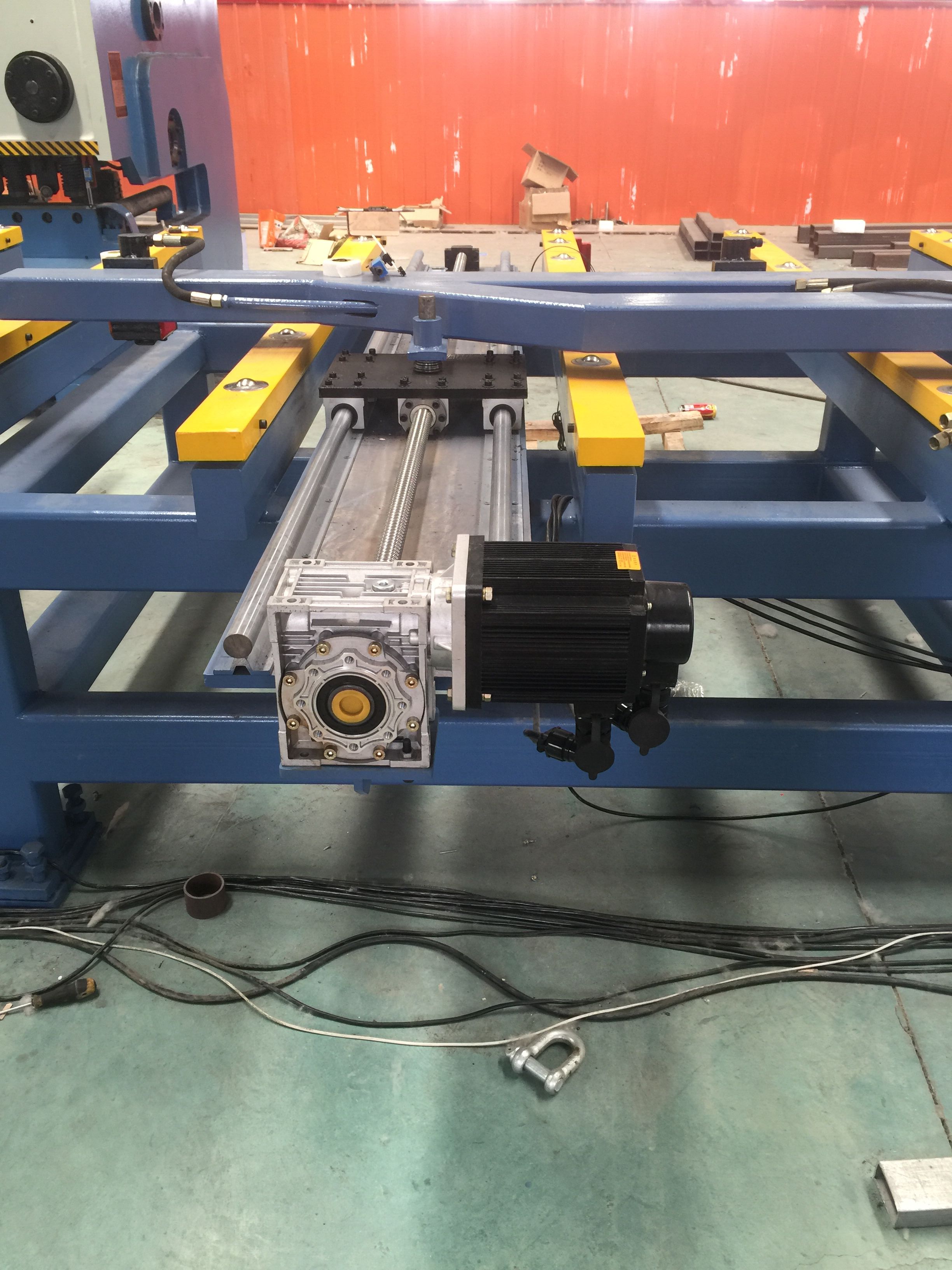

Control System:PLC

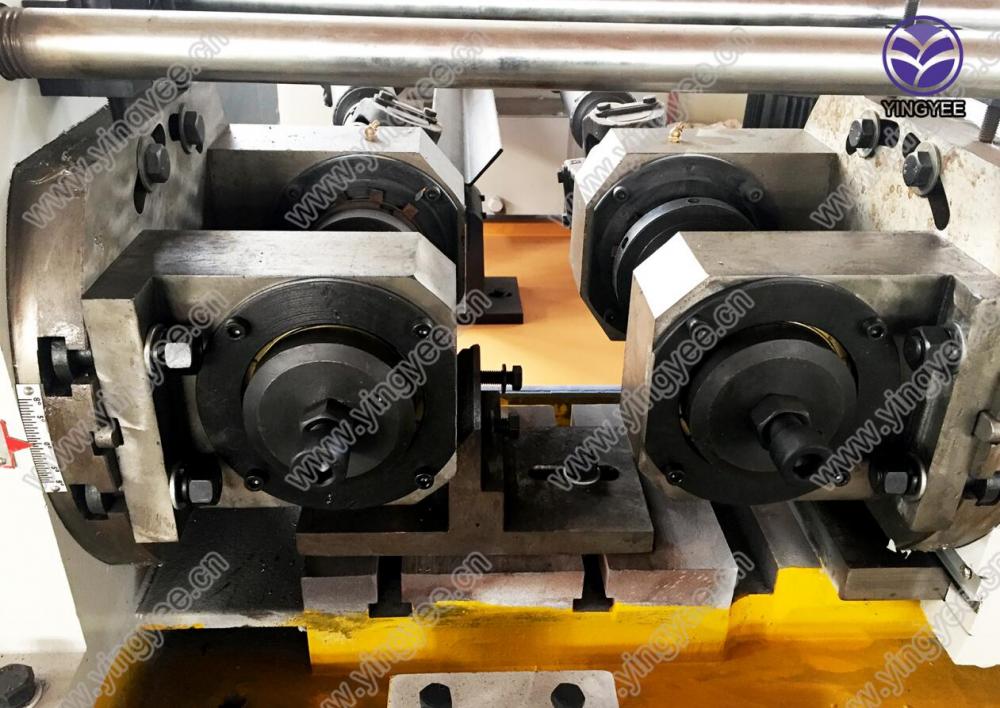

Material Of Cutting Blade:Cr12

After Service:Engineers Available To Service Machinery Overseas

Voltage:380V/3Phase/50Hz Or At Your Request

Cutting Mode:Hydraulic Cutting Or Electric Cutting

Forming Speed:8-10m/min

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

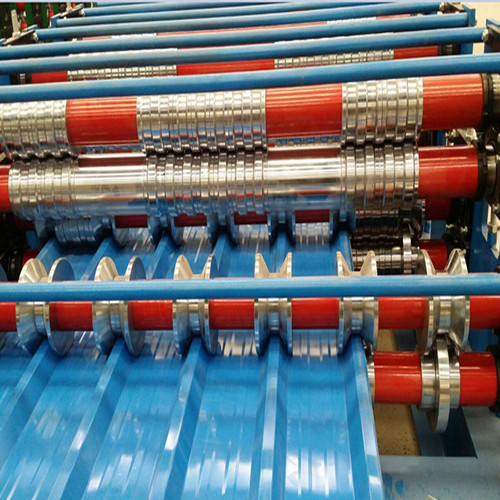

Color sheel sheet Shearing Machine Shearing machine using steel plate welded structure,vibration welding residual stress elimination has dood rigidity and stability,knife overall annealing;

The machine use the iron welded construction, and it can

Hydraulic shearing machine

New Style electric shearing machine with movable blade system

1.Have Reliable safety guards

2.Full welded steel structure, stress released, with rigidity and reliable well kept.

3.Main frame composes of uprights, worktable, holding-down cylinder and oil tank.

4.Blade material 6CrW2Si with hardness HRC58-60, with quality shearing result and long life

5.Main electrical components (contactors and switches) are Siemens, Germany.

Technical parameters:

1. Thickness:3mm‐20mm

2. Max length :12‐15M

3. Max cutting width: 900-1200mm 4. Speed for cutting: 8‐10m/min 5. Main power: 30Kw(20mm) 20Kw(18mm) 15Kw(12mm) 6. Moving motor: 5.5Kw 7. Cutting angles: 0.5‐3° 8. Height of platform: 1030mm 9. Workshop dimension: 100 ㎡ 10. Servo motor to control the length of the material, 3 pcs PLC Coordinated control Brand of Electrical components:

1. Touch screen:Delta

2. PLC Delta

3. Relay:schneider 4. Circuit breaker Chint 5. Encoder:omron 6. Bottom schneider 7. Inventor Shihlin

Pictures of machine:

Our advantage:

1. Short delivery period.

2. Effective communication

3. Interface customized.

Looking for ideal Steel Sheet Cutting Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Roof Sheet Shearing Machine are quality guaranteed. We are China Origin Factory of Hydraulic Guillotine Shearing Machine. If you have any question, please feel free to contact us.

Product Categories : Shearing Machine

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for Newly Arrival Gutter Cold Roll Forming Machine - Color sheel sheet Shearing Machine – Yingyee, The product will supply to all over the world, such as: Amman, Israel, Ukraine, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!