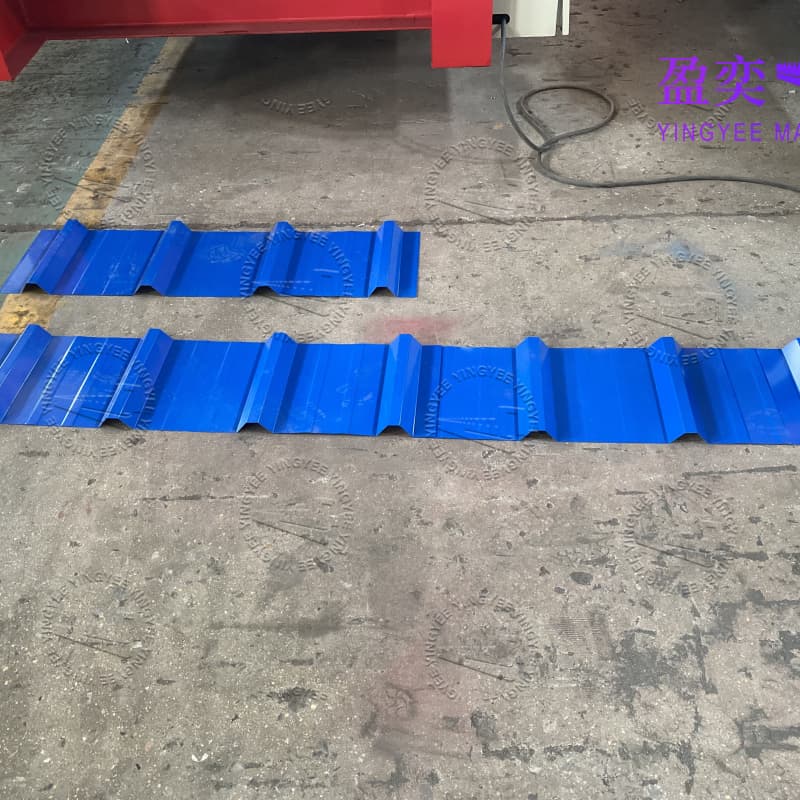

IBR colored roofing sheet roll forming machine

Short Description:

Basic Info

Control System:PLC

Warranty:12 Months

Thickness:0.3-1mm

Using:Roof

Type:Roof Sheet Roll Forming Machine

Forming Speed:25-30m/min

Voltage:38oV/3Phase/50Hz Or At Customer’s Request

Material:GI, PPGI, Aluminum Coils

Cutting Mode:Hydraulic

Delivery:30 Days

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin Xingang

Product Description

IBR trapezoid Roof Sheet Roll Forming Machine

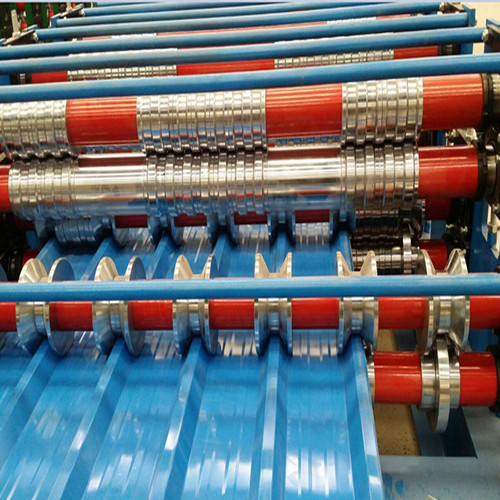

The sheet coil is loaded into spindle of decoiler, radial expand to fix the coil. The coil is fed into roll forming machine, after a continuous bending operation in which coil sheet is passed through consecutive sets of roller stands, steel strip is formed into required panel. Hydraulic cutting device cut the finished product into required length. Control cabinet adopts touch screen operation,control machine speed, cutting length, product quantity, etc.

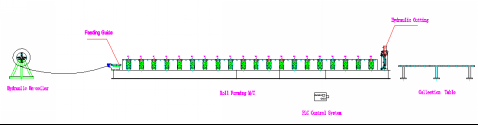

Working Flow: Decoiler – Feeding Guide – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting – Output Table

Technical parameters:

| Raw materials | Galvanized coils, Pre-painted coils, Aluminum coils |

| Material thickness range | 0.2-1mm |

| Forming speed | 10-15m/min |

| Rollers | 15 rows(according to drawings) |

| Material of rollers | 45# steel with chromed |

| Shaft material and diameter | 76mm, material is 40Cr |

| Material of body | 400H steel |

| Wall panel | 20mm Q195 steel(all with electrostatic spraying) |

| Controlling system | PLC |

| Main power | 5.5KW |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Voltage | 380V/3Phase/50Hz |

| Total weight | about 4 tons |

Pictures of machine: