High definition Standing Seam Roofing Machine - Mould cutting downpipe roll forming machine – Yingyee

Short Description:

High definition Standing Seam Roofing Machine - Mould cutting downpipe roll forming machine – Yingyee Detail:

Basic Info

Delivery Time:30 Days

Warranty:12 Months

After Service:Engineers Available To Service Machinery Overseas

Type:Pipe Production Line

Cutting Mode:Flying Saw Cutting Or Mould Cutting

Material:GI, PPGI, Aluminum Coils

Material Of Cutting Blade:Cr12

Forming Speed:25-30m/min

Voltage:380V/3Phase/50Hz Or At Your Request

Way Of Driven:Chain Or Gear Box

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

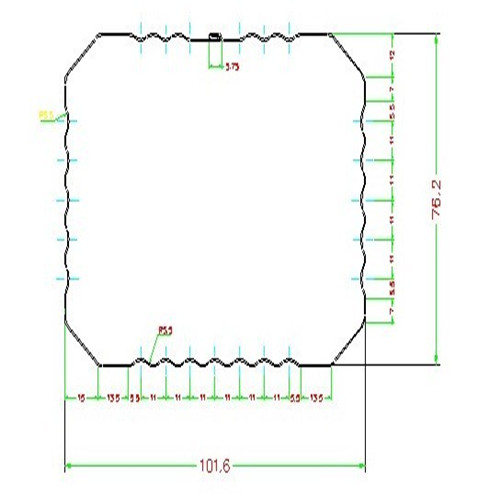

Round downpipe downspout roll forming machine

Mould cutting Downpipe Roll Forming Machine with draw bender,Incision neatly, easy to install and operate, and we are up to date with the latest technology and improve our machines according to market demand

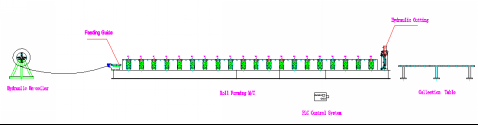

Working Flow: Decoiler – Feeding guide – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting – Output Table

Technical parameters:

| Raw material | PPGI or GI |

| Material thickness range | 0.2-0.8mm |

| Rollers | 18 rows |

| Material of forming rollers | 45# steel with chromed |

| Shaft diameter and mateiral | 76mm, material is 40Cr |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Forming speed | 12-15m/min(excluding cutting stoping time) |

| Main motor power | 4 KW |

| Hydraulic station power | 3KW |

| Mode of cutting | Hydraulic cutting or flying saw cutting or mould cutting |

| Control system | PLC Frequency Control System with touch screen |

Pictures of machine:

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal Downspout Making Machinery Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Mould Cutting Downspout Machine are quality guaranteed. We are China Origin Factory of Roll Forming Machine Europe. If you have any question, please feel free to contact us.

Product Categories : Downpipe Roll Forming Machine > Round Downpipe Roll Forming Machine

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for High definition Standing Seam Roofing Machine - Mould cutting downpipe roll forming machine – Yingyee, The product will supply to all over the world, such as: Turkmenistan, Slovakia, San Diego, We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!