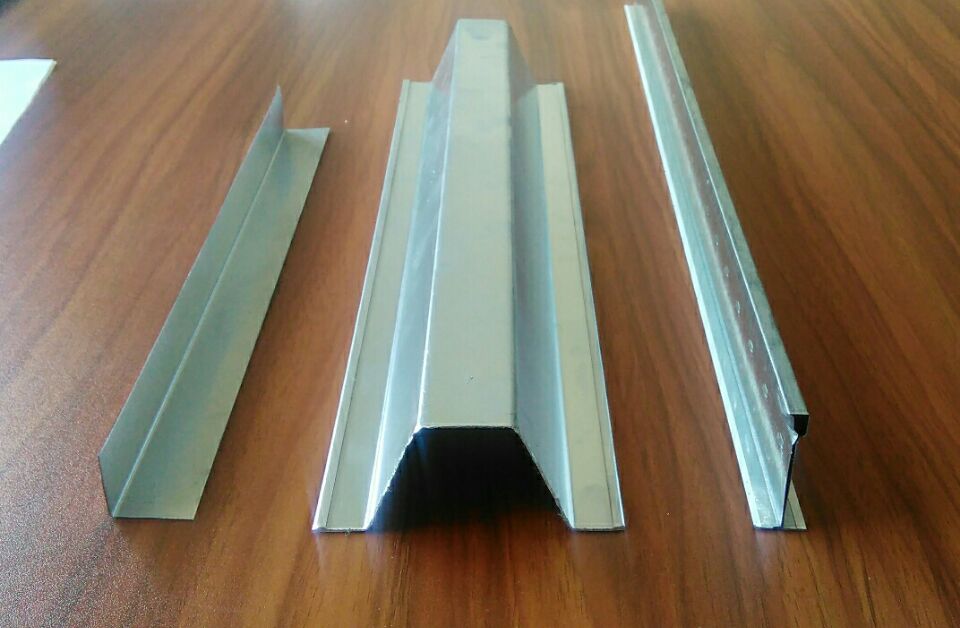

Factory best selling China Galvanized Light Steel Keel Metal Profiles Drywall Stud Track

Short Description:

Our mission is always to develop into an innovative supplier of high-tech digital and communication devices by offering price added design, world-class manufacturing, and repair capabilities for Factory best selling China Galvanized Light Steel Keel Metal Profiles Drywall Stud Track, Our business has already set up a experienced, creative and responsible staff to create shoppers together with the multi-win principle.

Our mission is always to develop into an innovative supplier of high-tech digital and communication devices by offering price added design, world-class manufacturing, and repair capabilities for China Light Steel Keel, Metal Stud, Our products are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

Basic Info

Control System:PLC

Delivery Time:30 Days

Warranty:12 Months

Material Of Cutting Blade:Cr12

Type:Steel Frame & Purlin Machine

After Service:Engineers Available To Service Machinery Overseas

Voltage:380V/3Phase/50Hz Or At Your Request

Way Of Driven:Chain Or Gear Box

Forming Speed:30-40m/min(excluding Punching)

Cutting Mode:Servo Tracking Cutting

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin Xingang

Product Description

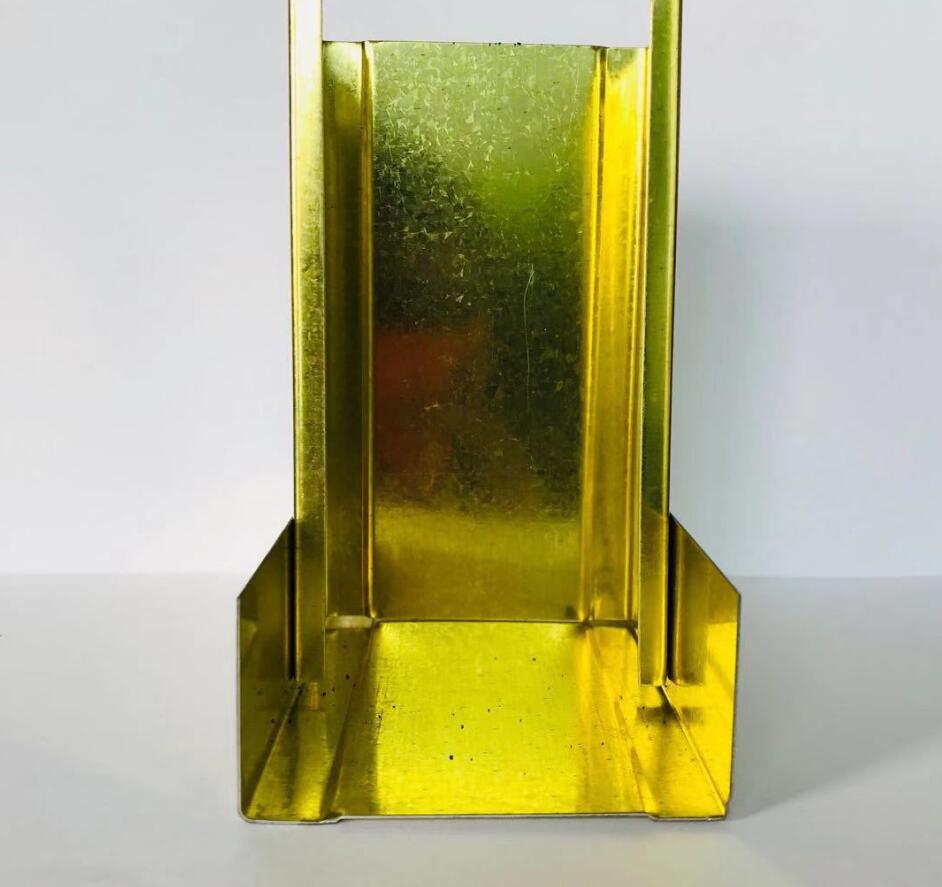

Stud And Track Keel Forming Machine

Steel Tile Roll Forming Machine adopts new station to increase the solidity of the machine; products are widely used in modern architecture roofing, the product increased the housing aesthetics.

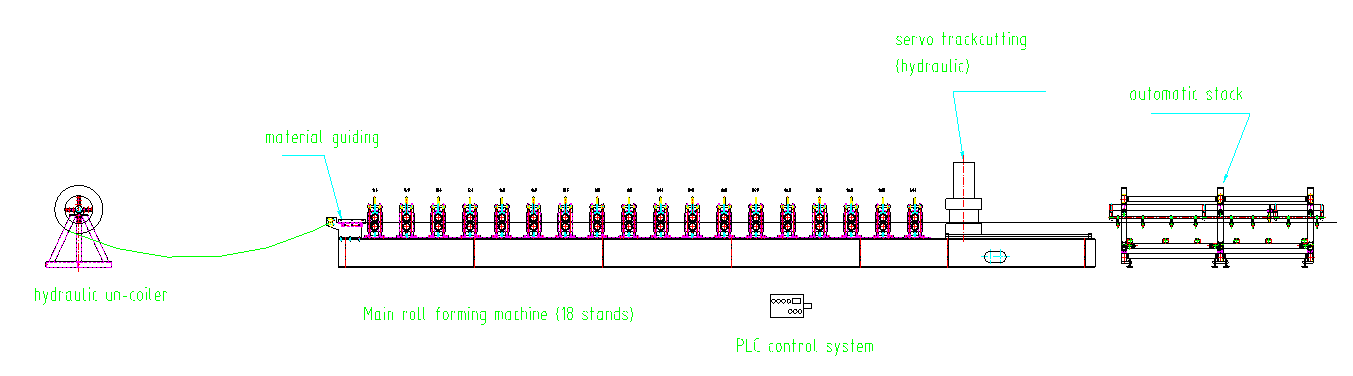

Working process:

Decoiler – Feeding guide – Straighteing – Main roll forming machine – PLC control system – Servo tracking cutting – Receiving table

Technical parameters:

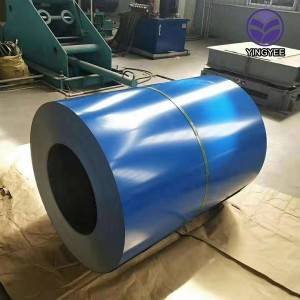

Raw material

PPGI, GI, Aluminum coils

Material thickness range

0.3-1mm

Forming speed

30-40m/min(without punching)

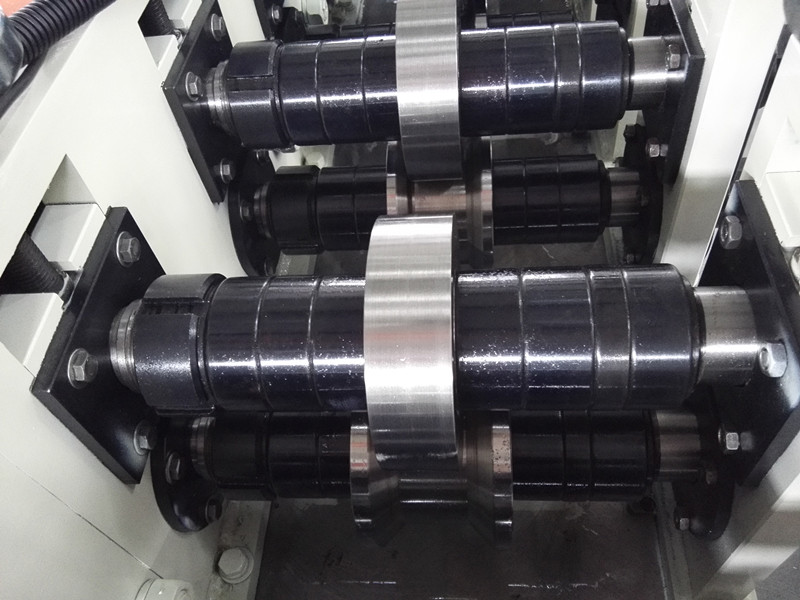

Rollers

12 rows

Material of forming rollers

45# steel with chromed

Shaft diameter and material

40mm, material is 40Cr

Controlling system

PLC

Cutting mode

Servo tracking cutting

Material of cutting blade

Cr12 mould steel with quenched treatment

Voltage

380V/3Phase/50Hz or at your requirement

Main motor power

4KW

Hydraulic station power

3KW

Way of driven

Gear box

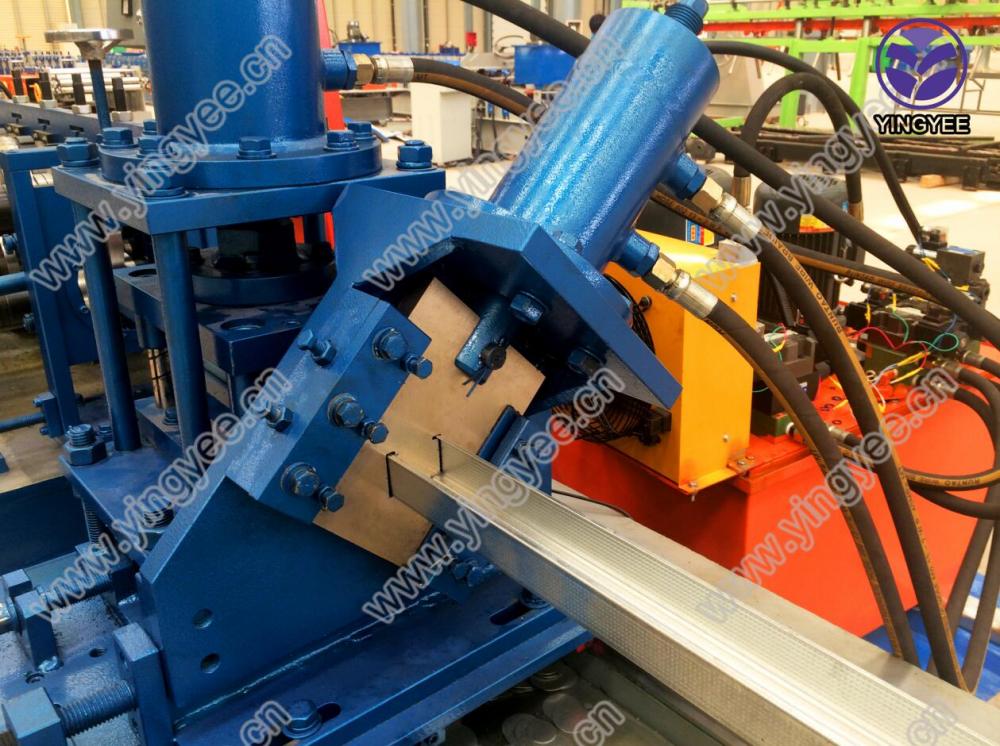

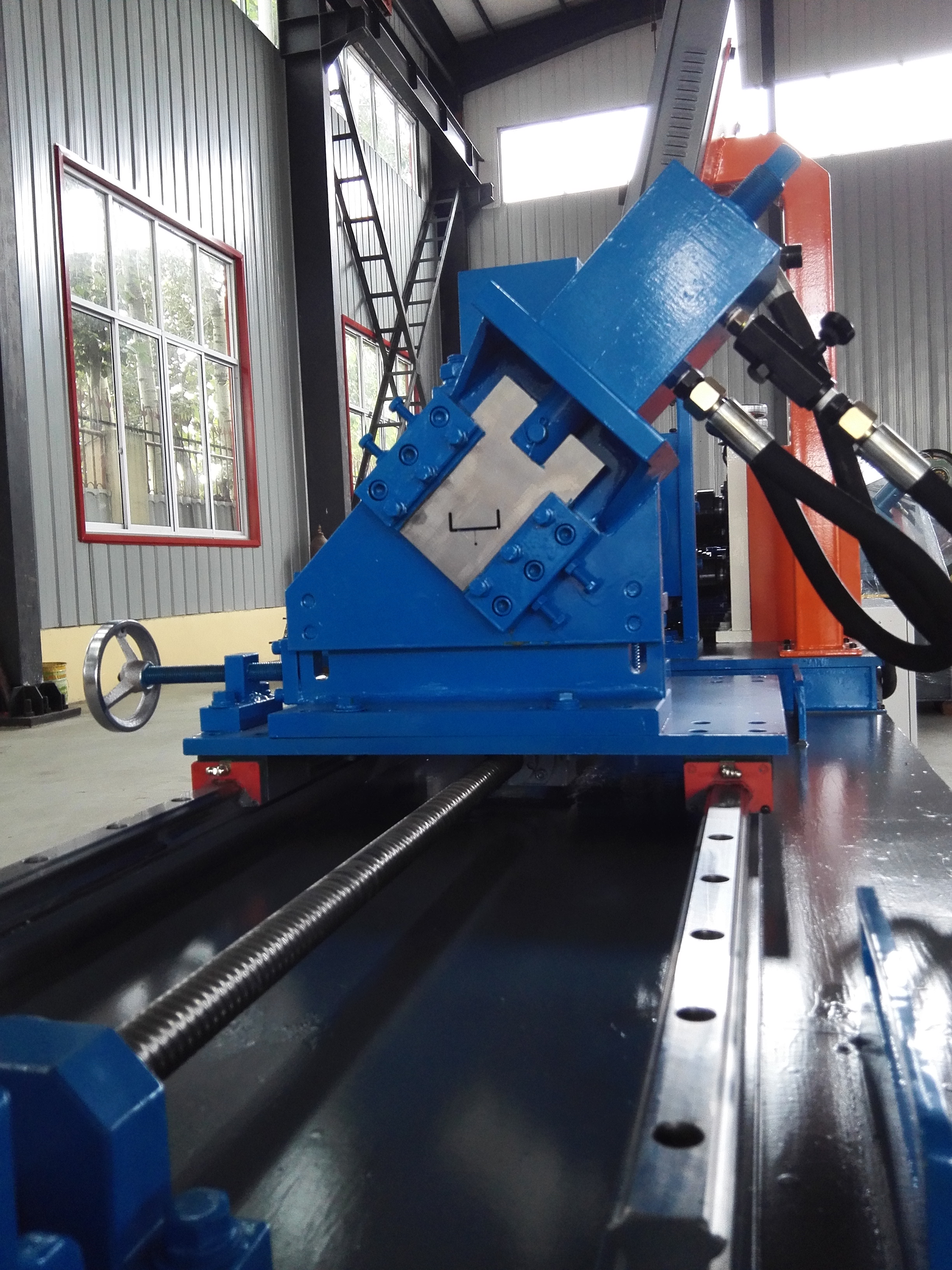

Pictures of machine:

Company information:

YINGYEE MACHINERY AND TECHNOLOGY SERVICE CO.,LTD

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor formal the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment. Our products were sold to more than 20 countries already. Also included US and Germany. Main product :

- Roof roll forming machine

- Roller Shutter Door Roll Forming Machine

- C and Z purlin roll forming machine

- Downpipe Roll Forming Machine

- Light Keel Roll Forming Machine

- Shearing Machine

- Hydraulic decoiler

- Bending machine

- Slitting machine

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal Stud Track Light Keel Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Light Weight Stud And Track Keel are quality guaranteed. We are China Origin Factory of Heavy Duty Stud and Track Keel. If you have any question, please feel free to contact us.

Product Categories : Light Keel Roll Forming Machine > Stud And Track Light Keel Forming Machine