Quality Inspection for Steel Tube Mill - automatic double layer roof sheet forming machine – Yingyee

Short Description:

Quality Inspection for Steel Tube Mill - automatic double layer roof sheet forming machine – Yingyee Detail:

Basic Info

Type:Roof Sheet Roll Forming Machine

Waranty:12 Months

Delivery Time:30 Days

Material:Color Coated Steel, Galvanized Steel, Aluminum St

Forming Speed:25-30m/min(excluding Cutting Time)

Cutting Mode:Hydraulic

Way Of Driven:Chain Transmission

Control System:PLC

Voltage:As Customer’s Request

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin Xingang

Product Description

Double Layer Roll Forming Machine

Automatic color Steel Double Layer Roof Forming Machine applicable to commercial facade, garage, shopping malls, hospitals, factories and mines enterprises and so on public place or residence. Especially it was large and inconvenient installation ground body place convenient and quick open.

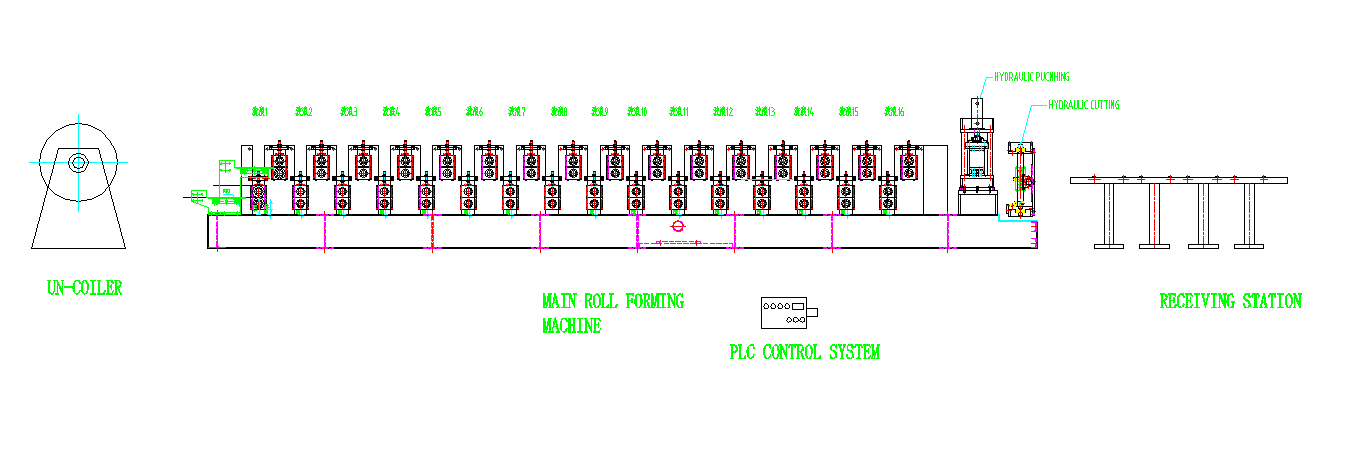

Working Flow: Decoiler – Feeding Guide – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting – Output Table

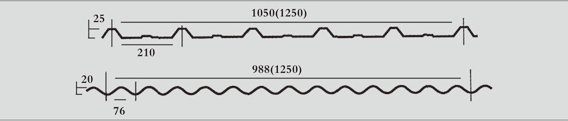

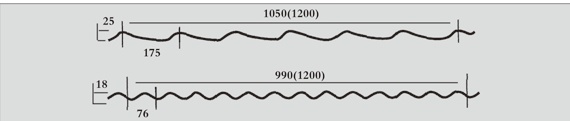

Technical parameters:

Raw material

Color coated steel, Galvaznized steel, Aluminum steel

Material thickness range

0.3-1mm

Rolles

11-18 rows(according to drawings)

Material of rollers

45# steel with chromed

Forming speed

25-30m/min

Shaft material and diameter

75mm, material is 40Cr

Main motor power

5.5KW-7.5KW

Hydraulic station power

5.5KW

Material of cutting blade

Cr12 mould steel with quenched treatment

Uncoiler’s loading capacity Max. Capacity

5tons(can be increased to be 10 tons)

Controlling system

Mitsubishi PLC & converter

Voltage

380V/3Phase/50Hz(or at buyer’s requirements)

Pictures of machine:

Company information:

YINGYEE MACHINERY AND TECHNOLOGY SERVICE CO.,LTD

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor formal the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment. Our products were sold to more than 20 countries already. Also included US and Germany. Main product :

- Roof roll forming machine

- Roller Shutter Door Roll Forming Machine

- C and Z purlin roll forming machine

- Downpipe Roll Forming Machine

- Light Keel Roll Forming Machine

- Shearing Machine

- Hydraulic decoiler

- Bending machine

- Slitting machine

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal Sale Double Layer Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Automatic Double Layer Roll Forming Machine are quality guaranteed. We are China Origin Factory of Steel Double Layer Roof Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Roof Sheet Roll Forming Machine > Double Layer Roll Forming Machine

Product detail pictures:

Related Product Guide:

Responsible excellent and fantastic credit rating standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, buyer supreme" for Quality Inspection for Steel Tube Mill - automatic double layer roof sheet forming machine – Yingyee, The product will supply to all over the world, such as: Lithuania, Nigeria, Pretoria, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We're confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.