OEM Manufacturer Stud And Track Frame Forming Machine - Perforated Cable Tray Cold Roll Forming Machine – Yingyee

Short Description:

OEM Manufacturer Stud And Track Frame Forming Machine - Perforated Cable Tray Cold Roll Forming Machine – Yingyee Detail:

Basic Info

Warranty:12 Months

Delivery Time:30 Days

After Service:Engineers Available To Service Machinery Overseas

Forming Speed:25-30m/min(excluding Punching)

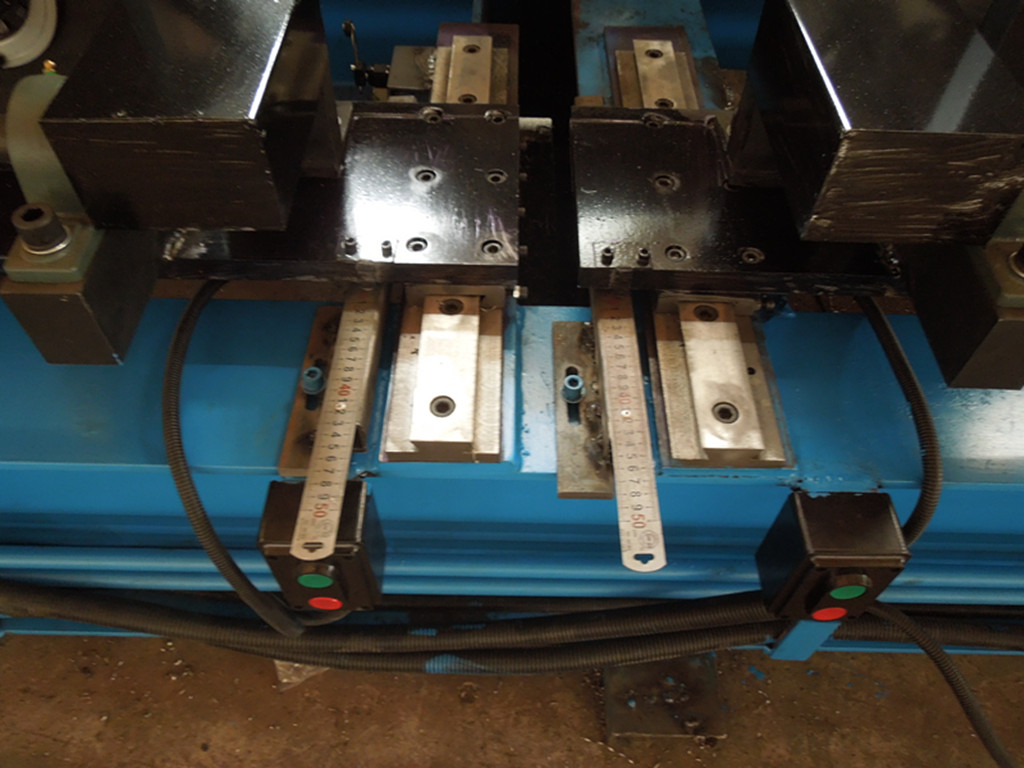

Cutting Mode:Hydraulic

Material Of Cutting Blade:Cr12

Type:Steel Frame & Purlin Machine

Control System:PLC

Voltage:380V/3Phase/50Hz Or At Your Request

Way Of Driven:Chain Or Gear Box

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

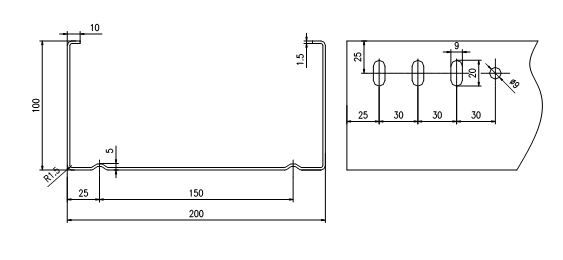

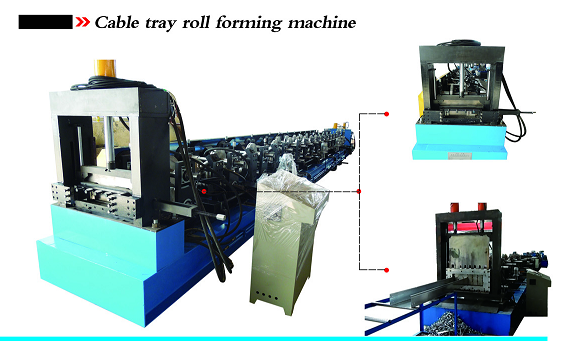

Perforated Cable Tray Cold Roll Forming Machine

A cable tray system, is “a unit or assembly of units or sections and associated fittings forming a rigid structural system used to securely fasten or support cables and raceways.” Cable trays are used to hold up and distribute cables. Cable Tray Roll Forming Machine is special designed for its production.

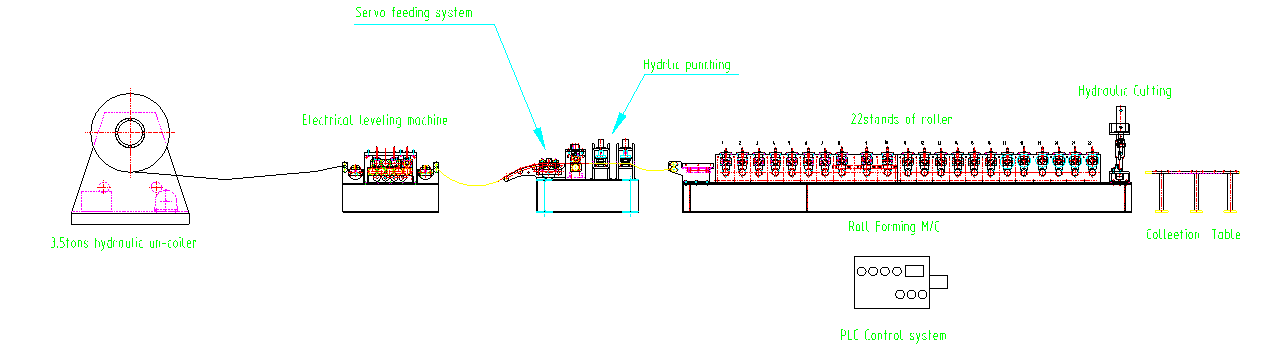

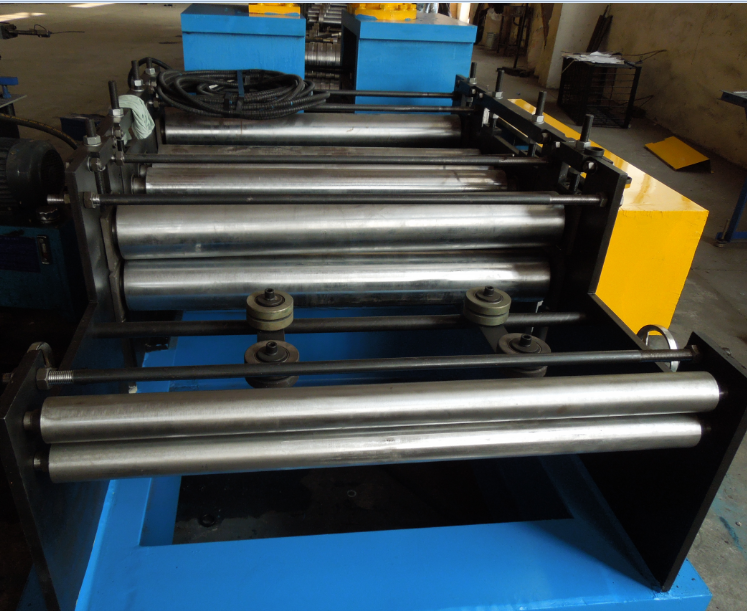

Working Flow: Decoiler – Feeding Guide – Servo feeding system – Hydraulic punching – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting – Output Table

Technical parameters:

| Matching material | Galvanized or PPGI, Aluminum coils |

| Material thickness range | 0.8mm-2.0mm |

| Forming speed | 20-30m/min(excluding punching and cutting time) |

| Hydraulic station power | 22KW |

| Rollers | 20(according to drawings and size) |

| Shaft material and diameter | 80mm, material is 40Cr |

| Material of the body | 400H steel |

| Wall panel | 20mm, Q195 steel(all with electrostatic spraying) |

| Controlling system | PLC |

| Material of rollers | 45# steel with chromed or Cr12(you can choose the material as your request) |

| Material of blade | Cr12 mould steel with quenched treatment 58-62℃ |

| Total weight | About 5 tons |

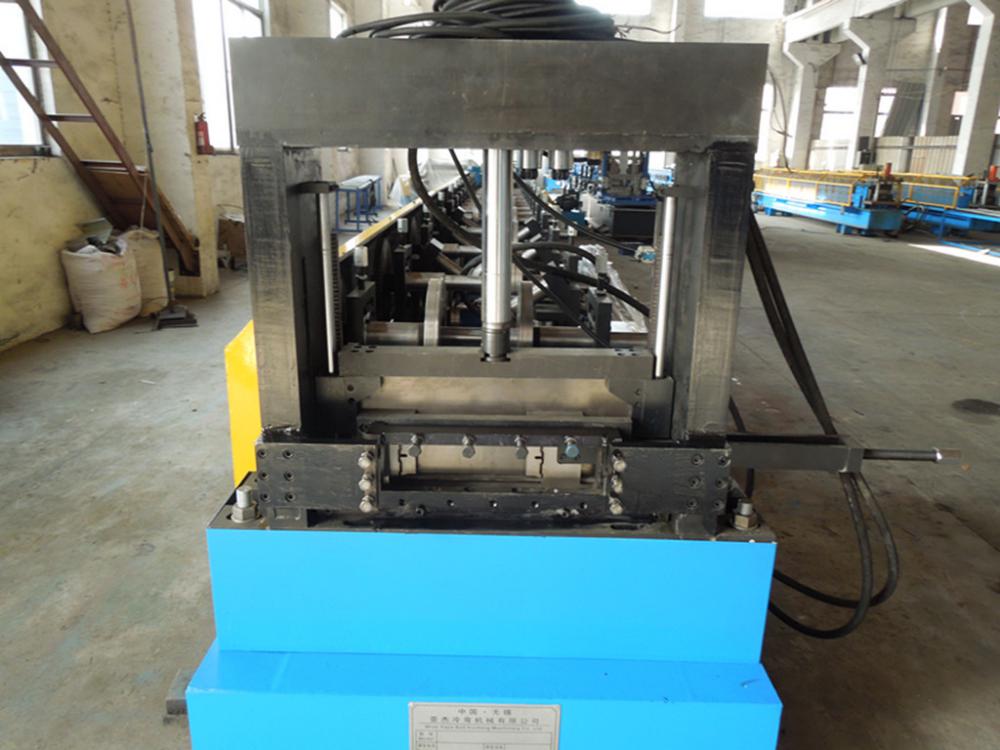

Pictures of machine:

Company information:

YINGYEE MACHINERY AND TECHNOLOGY SERVICE CO.,LTD

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor formal the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment. Our products were sold to more than 20 countries already. Also included US and Germany. Main product :

- Roof roll forming machine

- Roller Shutter Door Roll Forming Machine

- C and Z purlin roll forming machine

- Downpipe Roll Forming Machine

- Light Keel Roll Forming Machine

- Shearing Machine

- Hydraulic decoiler

- Bending machine

- Slitting machine

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal Roll Foming Making Machinery Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Wholesale Cable Tray Roll Forming Machine are quality guaranteed. We are China Origin Factory of Roll Forming Machine Price. If you have any question, please feel free to contact us.

Product Categories : Cable Tray Roll Forming Machine

Product detail pictures:

Related Product Guide:

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for OEM Manufacturer Stud And Track Frame Forming Machine - Perforated Cable Tray Cold Roll Forming Machine – Yingyee, The product will supply to all over the world, such as: Kazakhstan, Seychelles, Croatia, There are advanced producing & processing equipment and skilled workers to ensure the products with high quality. We have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our products are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.