New Fashion Design for Rain Downspout Forming Machine - Metal Ridge Cap Roll Former – Yingyee

Short Description:

New Fashion Design for Rain Downspout Forming Machine - Metal Ridge Cap Roll Former – Yingyee Detail:

Basic Info

Type:Roof Sheet Roll Forming Machine

Warranty:12 Months

Delivery Time:30 Days

Using:Roof

Cutting Mode:Hydraulic

Material Of Cutting Blade:Cr12

Control System:PLC

Material:Colored Steel, Galvanized Steel, Aluminum Steel

Forming Speed:15-20m/min(without Press)

Voltage:At Customer’s Request

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

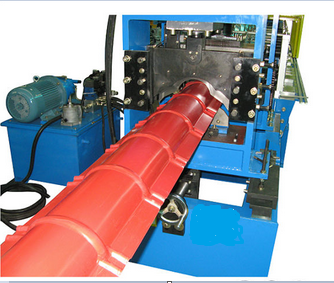

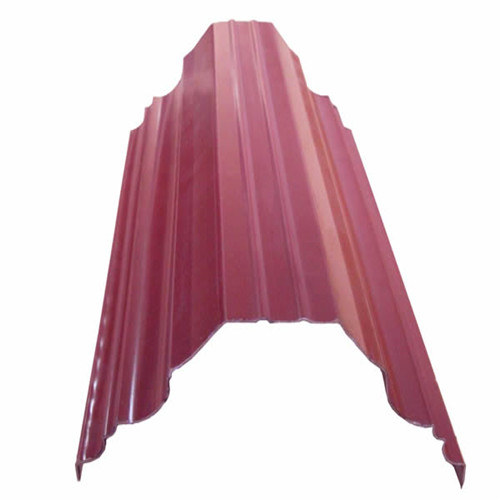

Metal Ridge Cap Roll Former Roof Tile Metal Sheet Forming Machine

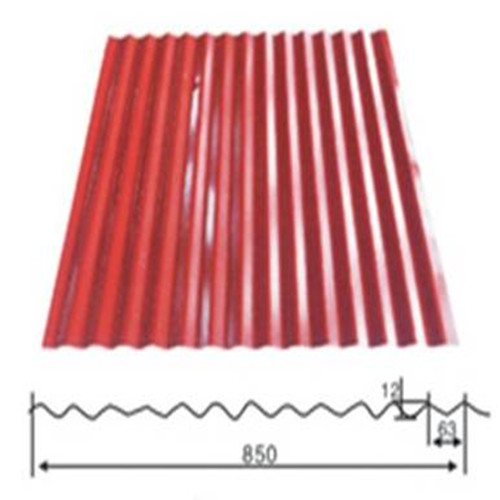

The coil width of Metal Ridge Cap Tile Making Machine is usually from 300-550mm. The thickness of Metal Ridge Cap Tile Making Machine is between 0.25-08mm.Ridge Cap Roof Tile Roll Forming Machine can continuous form the steel sheet according to customer`s requirement, automatically cut to length.

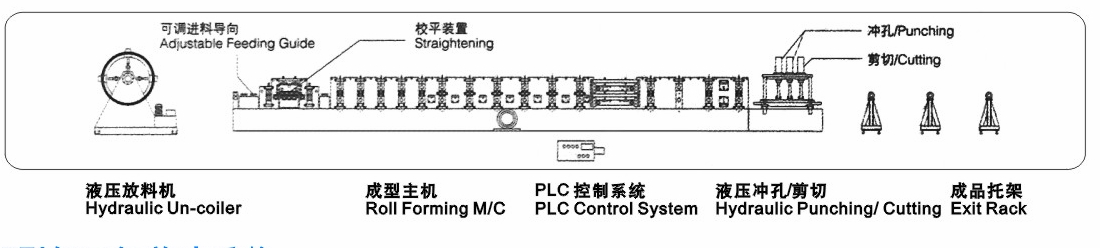

Working Flow: Decoiler – Feeding Guide – Straightening – Main Roll Forming Machine – PLC Contol System – Press – Hydraulic Cutting – Output Table

Technical parameters:

| Raw material | Colored steel, Galvanized steel, Aluminum steel |

| Material thickness range | 0.25-0.8mm |

| Rollers | 16 rows(according to drawings) |

| Material of rollers | 45# steel with chromed |

| Shaft diameter and diameter | 60mm, material is 40Cr |

| Cutting mode | Hydraulic |

| Material of cutting blade | Cr12Mov with quench HRC58-62° |

| Forming speed | 15-20m/min(without press) |

| Controlling system | PLC |

| Main motor power | 7.5KW |

| Hydraulic station power | 3KW |

Pictures of machine:

Looking for ideal Metal Sheet Ridge Cap Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Ridge Cap Roof Tile Rolling Machine are quality guaranteed. We are China Origin Factory of Ridge Cap Making Machine. If you have any question, please feel free to contact us.

Product Categories : Roof Sheet Roll Forming Machine > Ridge Cap Tile Roll Forming Machine

Product detail pictures:

Related Product Guide:

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for New Fashion Design for Rain Downspout Forming Machine - Metal Ridge Cap Roll Former – Yingyee, The product will supply to all over the world, such as: Karachi, Mozambique, Dubai, Our items are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.