New Delivery for Tube Mill Line - Glazed Tile Roof Panel Machine with gear box – Yingyee

Short Description:

New Delivery for Tube Mill Line - Glazed Tile Roof Panel Machine with gear box – Yingyee Detail:

Type:Roof Sheet Roll Forming Machine

Using:Roof

Material:PPGI, GI, Aluminum Coils

Cutting Mode:Hydraulic

Driven way: By Gear Box

Material Of Cutting Blade:Cr12 Mould Steel With Quenched Treatment

Control System:PLC

Voltage:380V/3Phase/50Hz Or At Customer’s Request

Warranty:12 Months

Delivery Time:30 Days

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

Glazed Tile Roof Panel Machine

Glazed tile steel roofing machine can produce different shapes of steel roof by different roof panel machines, wall sheets according to the clients’ profile drawings and requirement. Metal Glazed Tile Machine is new building materials with various thickness and colors. Glazed tile steel roofing machine has many advantages, such as low cost, easy installation, short building period, re-cycle use, beautiful appearance, and are light weight but high strength.

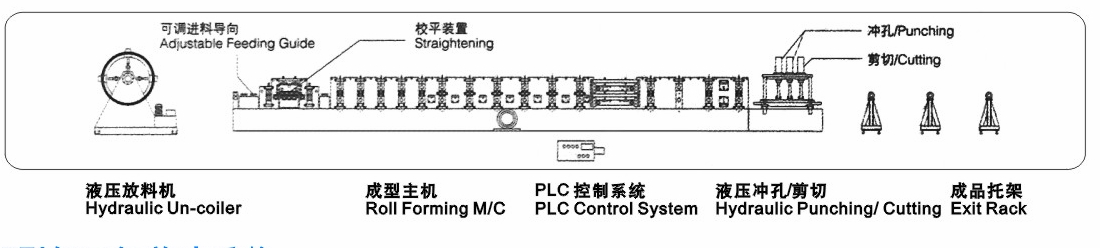

Working Flow: Decoiler – Feeding Guide – Straightening – Main Roll Forming Machine – PLC Contol System – Press – Hydraulic Cutting – Output Table

Technical parameters:

| Raw material | Colored steel, Galvanized steel, Aluminum steel |

| Material thickness range | 0.2-0.8mm |

| Rollers | 13 rows(according to drawings) |

| Material of roller | 45# steel with chromed |

| Forming speed | 15-20m/min(excluding press) |

| Shaft material and diameter | 75mm, material is 40Cr |

| Type of forming machine | single station with chain transmission |

| Controlling system | PLC & Transducer(Mitsubishi ) |

| Type of cutitng | Hydraulic cutting |

| Material of cutting blade | Cr12Mov with quench HRC58-62° |

| Voltage | 415V/3Phase/50Hz(or at buyer’s requirements) |

| Main motor power | 7.5KW |

| Hydraulic station power | 3KW |

Pictures:

Product detail pictures:

Related Product Guide:

To consistently enhance the management method by virtue of the rule of "sincerely, fantastic religion and top quality are the base of business development", we extensively absorb the essence of associated goods internationally, and constantly acquire new merchandise to satisfy the needs of shoppers for New Delivery for Tube Mill Line - Glazed Tile Roof Panel Machine with gear box – Yingyee, The product will supply to all over the world, such as: Macedonia, Angola, Mecca, Our market share of our products and solutions has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future. We've been looking forward to your inquiry and order.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!