Automated Shelf Panel Roll Forming System – Built for Speed & Accuracy

Short Description:

Product Name: Back Panel & Deck Panel Roll Forming Machine

Product Overview

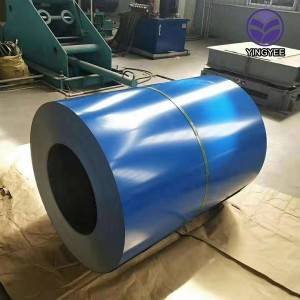

Our high-precision Storage Shelf Back Panel & Deck Panel Roll Forming Machine is engineered to be the cornerstone of efficient, automated shelving production. This fully integrated system transforms raw steel coils into finished back panels and decking panels in a single, continuous operation. Designed for manufacturers of pallet racking, cantilever racks, and industrial storage systems, it delivers unmatched consistency, speed, and material yield, transforming your production line into a competitive advantage.

Core Features & Advantages

1. High-Output, Dual-Function Design

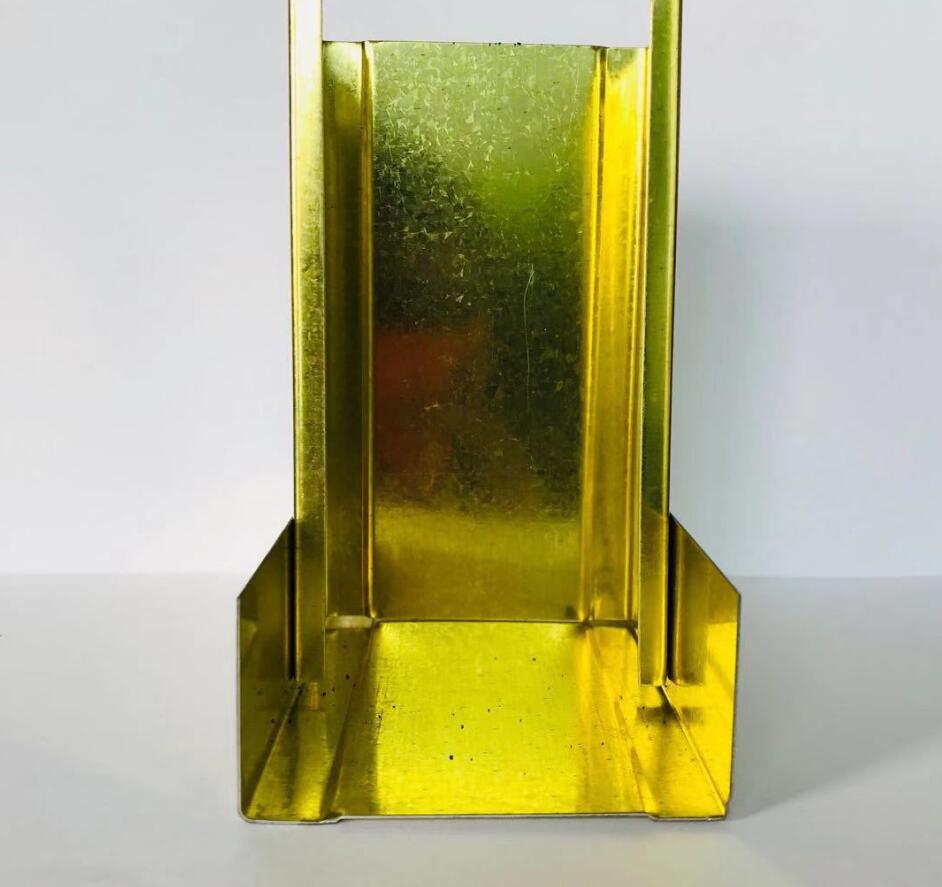

- Versatile Production: One machine, two critical components. Easily configured to produce both robust back panels (for structural stability) and reinforced deck panels (for superior load-bearing).

- Rapid Changeover: Quick-adjust roll forming stations and servo-driven controls minimize downtime when switching between profiles, maximizing your production flexibility.

2. Intelligent Automation & Control

- PLC Control System: User-friendly touchscreen interface for easy setup, speed adjustment, and fault diagnosis. Stores recipes for different panel specifications for instant recall.

- Automatic Feeding & Cutting: Servo-driven decoiler and precision fly shear or hydraulic cut-off ensure accurate length control and burr-free edges, ready for immediate assembly.

3. Built for Durability & Ease

- Heavy-Duty Construction: Fabricated from high-strength steel with precision-machined gearboxes and hardened forming rolls for long-term reliability under continuous operation.

- Low Maintenance Design: Easily accessible components and a centralized lubrication system reduce maintenance time and ensure optimal performance.

Send your message to us:

Write your message here and send it to us