Fully Automatic CZU Purlin Roll Forming Machine

Short Description:

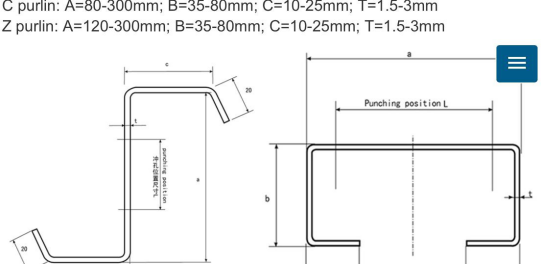

Drawings and Sizes

C Purlin Machine:

a: 80-300mm

b: 35-80mm

c: 10-25mm

T: 1.5-3mm

Z Purlin machine:

a: 120-300mm

b: 35-80mm

c:10-25mm

T: 1.5-3mm

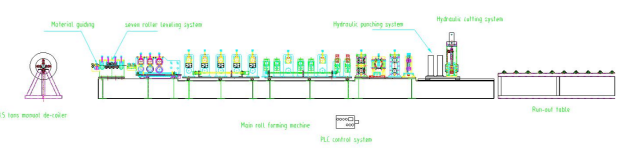

Working Process:

- 5 tons manual decoiler

- Straighten device

- Hydraulic Holes device

- Hydraulic Pre-cut device

- Main forming system

- All-size-in-one cut system

- Collecting table

- Control system PLC

|

NAME |

DESCRIPTION |

|

5 tons manual de-coiler

|

Inner dia: Ø440mm– Ø560mmMax input feeding: 600mmCapacity: 5Tonscoil outer diameter max 1500 mm |

|

Straighten device |

11 rollers for straighten 5 up and 6 down. |

|

Hydraulic Holes device |

Standard holes: 2 double holes and 1 single holeEach punching cylinder control each 2 holes for sides or single hole in the middleDistance flexible: a channel for the holes, the distance can operate by manualHole size flexible: to change the punching dies to change the size.The width distance between holes adjustable manual .it can’t control by PLC.The length distance between holes ,it can adjust by PLC. |

| Hydraulic Pre-cut device | Hydraulic Power, driven with gear |

|

Main forming system

|

Main power: 22kw6 electronic motors auto adjust size.Frame: 500mm H frame steelForming speed: 18-20m/minShaft material and diameters: #45 steel and fit side 65mm. Flexible side: 85mmRoller material: Gcr15. the hardness is HRC 52-55Steps: 15-18 steps for formingAll size change by PLC. All parameter set from the PLC control systemC/Z change, by manual change the rollers discretion

Machine size: L*W*H 11.5m*1.6m*1.4m (approx size. correct size will be known when machine ready) Machine weight about 12Tons Voltage: 380V/ 3phase/ 50 Hz(as customer require ) Driven way:Chain |

|

All-size-in-one cut system

|

Hydraulic cutting systemMaterial: Gcr12mov.All size in one blade |

|

Control system PLC |

Control the quality&punching length &cutting length automaticallyIn English languageThe machine will be stopped while it is punching and cuttingPLC must be able to keep in memory which profiles are inside machine even after the machine stoppedAutomatic length measures and quantity counting.Program batches with different profile lengths with no wasteSize of PLC about 700(L)*1000(H)*300(W)Encode: OMRONPLC : KAUTO (now auto adjust size only this brand) Solenoid valve: YUKEN (TAIWAN)

Frequency converter: DELTA Touch screen :WEINVIEW (TAIWAN) All connections to the machine and to PLC control Board are strong |

Send your message to us:

Write your message here and send it to us