Factory supplied Automatic Erw Tube Mill - EPS Sandwich Roof Panel Production Line – Yingyee

Short Description:

Factory supplied Automatic Erw Tube Mill - EPS Sandwich Roof Panel Production Line – Yingyee Detail:

Basic Info

Control System:PLC

Warranty:12 Months

Delivery Time:30 Days

Type:Roof Sheet Roll Forming Machine

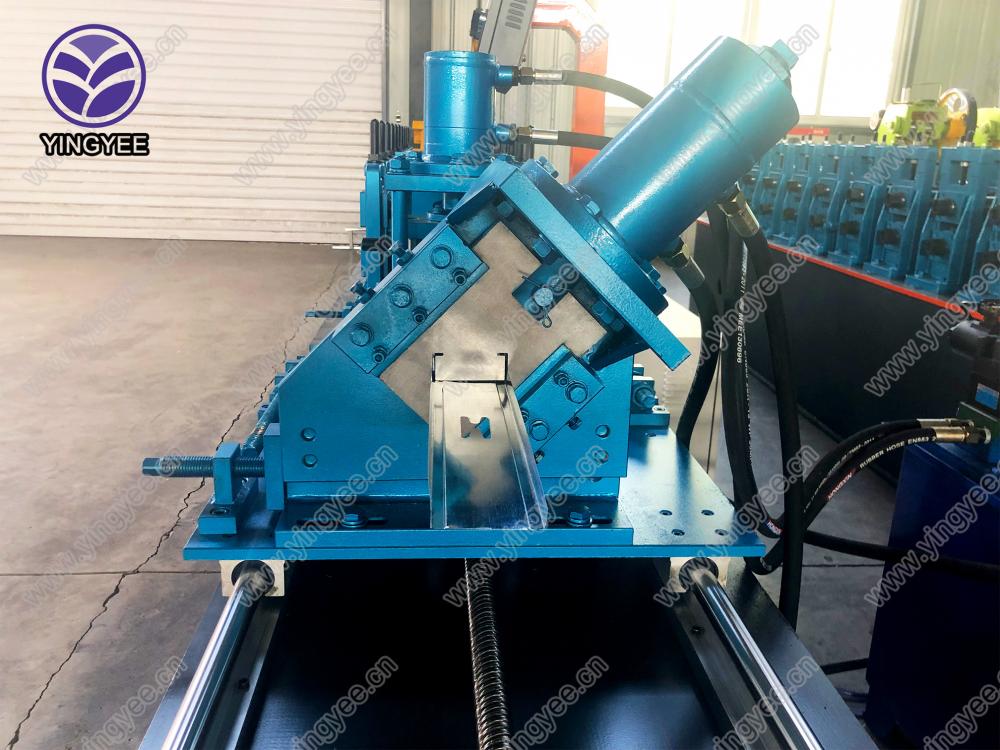

Cutting Mode:Hydraulic

Material:Color Coated Steel, Galvanized Steel, Aluminum St

Way Of Driven:Chain Transmission

Voltage:As Customer’s Request

After Service:Engineers Available To Service Machinery Overseas

Forming Speed:4-6m/min

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

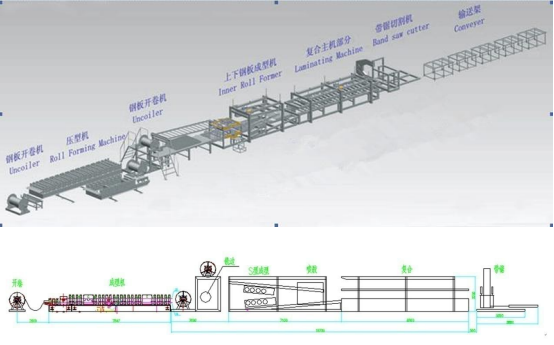

EPS sandwich roof panel production line

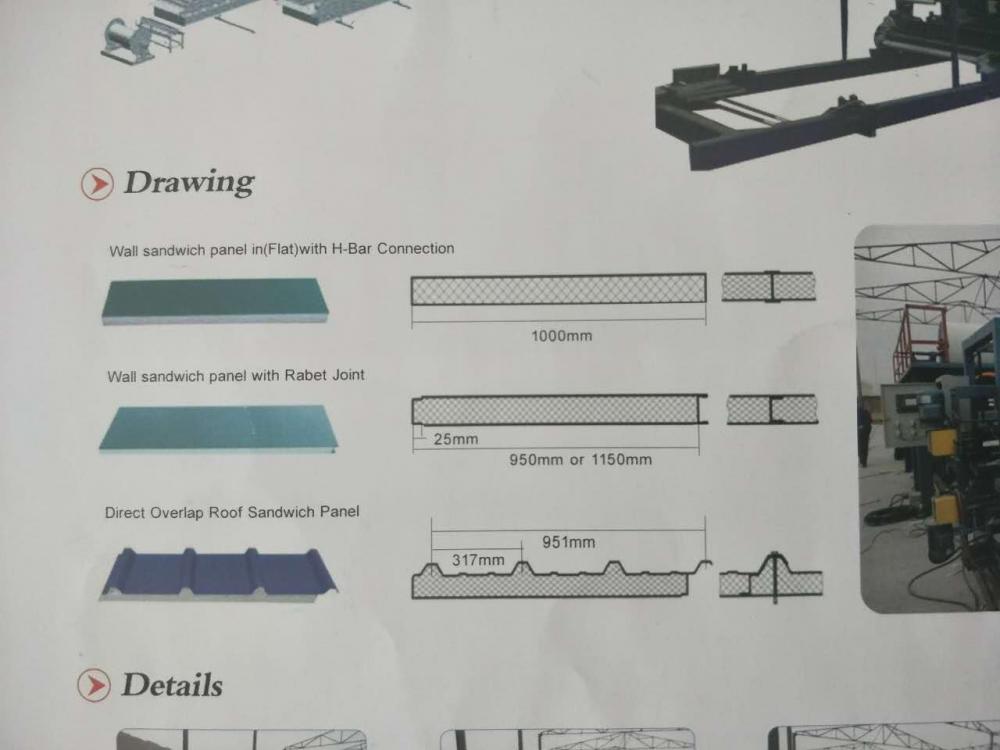

Professional Sandwich Panel Production Line is widely used as the roof and wall of factory, warehouse, garage, gymnasium, exhibition center, cinema, theatre, civil construction, stadium, cold storage, etc. Complex sheet forming machine has EPS and rock wool two types according to the material that complexed in the middle. The rock wool is superpior in fireproof performance. EPS usually expressed by capability, 0.8 every cube centimeter in a general way.

Technical parameters:

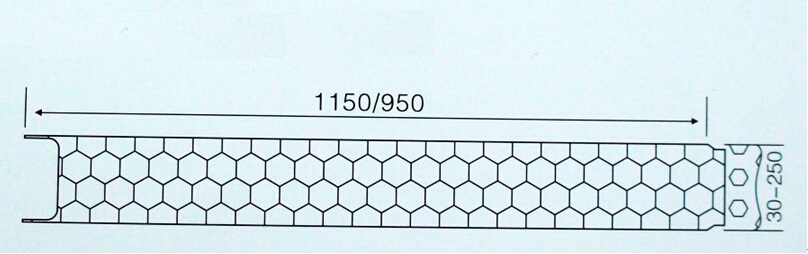

| Panel width | 950, 970,1150mm |

| Panel thickness | 50-200mm |

| Raw material | Galvanized coils, Pre-painted coils, Aluminum coils |

| Material thickness range | 0.3-0.7mm |

| width | 1000mm, 1250mm |

| yield strength | 235Mpa |

| Max coil weight | 5000kgs |

| working speed | 0-5m/min (adjustable) |

| Total length | about 35m |

| Control mode | PLC |

| Total power | about 30kw |

| Electricty condition | 380v/3phase/50hz (or depend on custmers requirement) |

Working process:

Pictures of machine:

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period.

2. Effective communication

3. Interface customized.

Looking for ideal Professional Sandwich Panel Production Line Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Sandwich Wall Panel Production Line are quality guaranteed. We are China Origin Factory of EPS Sandwich Roll Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Sandwich Panel Production Line

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High quality first" in mind, we do the job closely with our customers and supply them with efficient and skilled providers for Factory supplied Automatic Erw Tube Mill - EPS Sandwich Roof Panel Production Line – Yingyee, The product will supply to all over the world, such as: Holland, Italy, El Salvador, Providing Quality Products, Excellent Service, Competitive Prices and Prompt Delivery. Our products are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!