Electrical Box Flat Cap Forming Machine

Short Description:

Electrical box flat hat

It's function is rain proof.

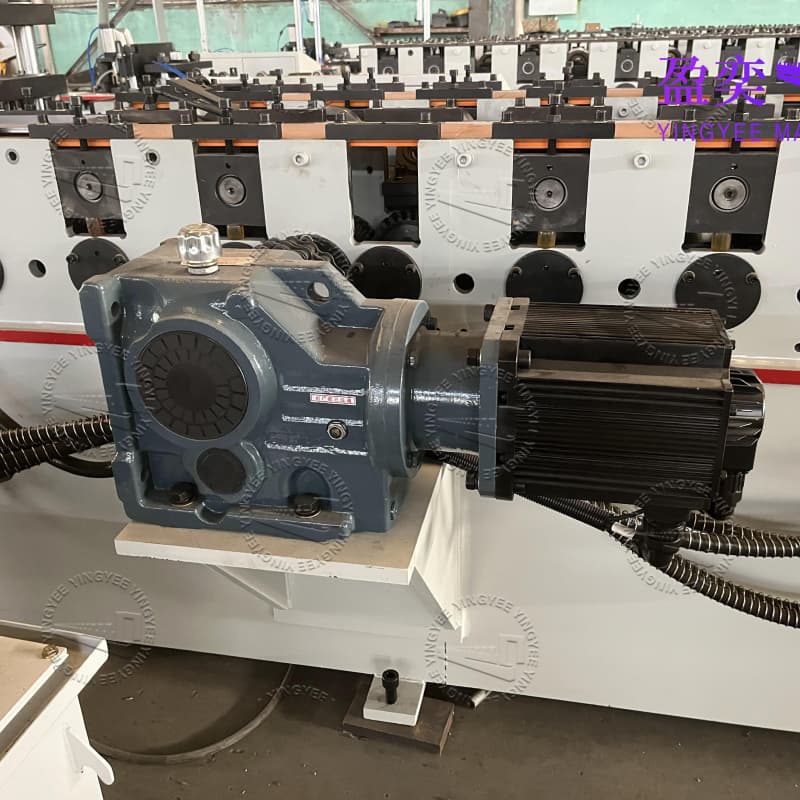

main motor is servo motor,high accuracy.

linear structure,long service life.

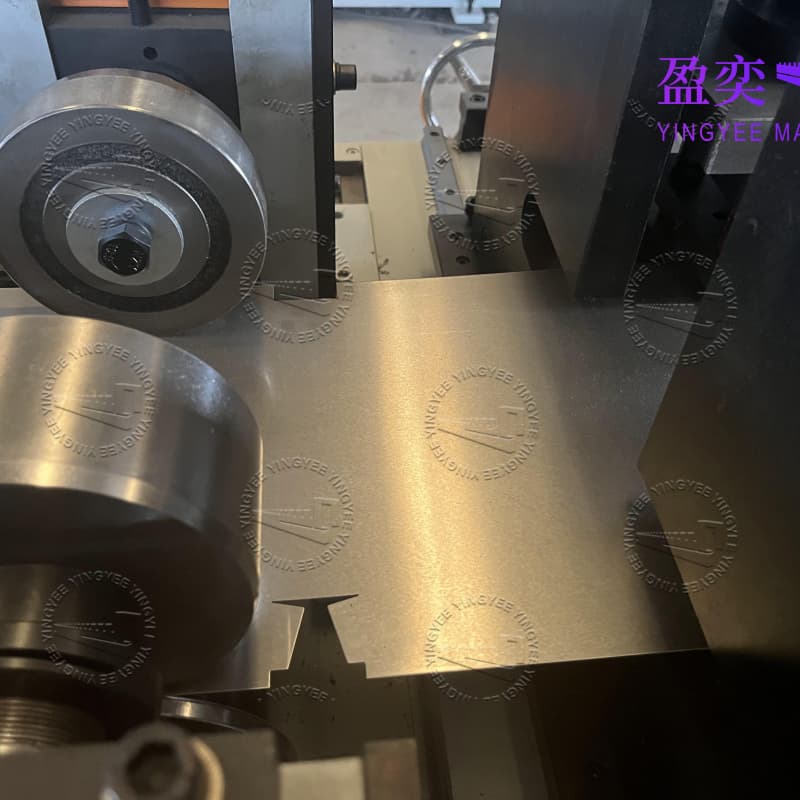

function cutting station, fold the lips and cut together.

high forming accuracy

The Electrical Box Flat Cap Forming Machine is a specialized cold roll forming system designed for the automated production of flat-top enclosures used in electrical distribution, control panels, and junction boxes. Ideal for manufacturing the top covers (flat hats) of electrical cabinets, this machine delivers high-speed, consistent, and dimensionally accurate profiles with excellent surface finish.

Key Features:

- Fully Automated Line: From decoiling, leveling, punching, roll forming, to cut-to-length — all processes integrated for seamless production.

- Customizable Profiles: Adjustable for various widths, heights, and thicknesses (typically 0.8–2.5mm), compatible with galvanized, pre-painted, or aluminum sheets.

- PLC Control System: Touchscreen HMI for easy operation, recipe storage, and fast changeover between sizes.

- Clean Cut-Off: Servo-controlled flying shear ensures burr-free, flat-end cuts for perfect fit during assembly.

Why Choose Our Machine?

- Increases production efficiency by up to 300% compared to manual methods

- Reduces labor costs and human error

- Ensures uniform quality for professional-grade electrical enclosures

- Compact design, low maintenance, and durable performance

Perfect for manufacturers in the electrical, construction, and OEM sectors looking for a reliable, turnkey solution for flat cap production.