Best Price on Steel Frame Roll Forming Machine - stone coated roofing tile production line – Yingyee

Short Description:

Best Price on Steel Frame Roll Forming Machine - stone coated roofing tile production line – Yingyee Detail:

Basic Info

Control System:PLC

Delivery Time:30 Days

Warranty:12 Months

Speed:5-6 Pieces

Cutting Mode:Hydraulic Cutting

Products:Roof Sheet Roll Forming Machine

Type:Roof

Voltage:As Customer’s Requirement

Material:Pre-printed Coil,galvanized Coil,Aluminum Co

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin Xingang

Product Description

Color stone supply for stone coated roofing tile production line

We developed stone coated ridage cap makine machine based on long time running and improvement. It is high-performance,stable, energy-efficient and easy operation. Meanwhile we also provide the whole line elements of the stone coated roofing tiles production line, and the material supply line.

Technical parameters:

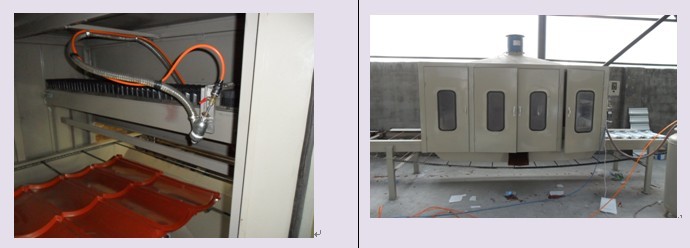

1. Auto bottom gule spraying section l Appearance size:4000*1000*2000 mm l Driving section:3KW Excitation motor or frequency speed regulation (as requirements ) l Automatic pressure spray tank:1set capability:200kg Range:0.6~1Mpa l Automatic glue machine motor: Servo motor, Power:750w, plc l Automatic spray gun:4 set(spare parts) l Dust collecting fan: 1set power:200w l Damp proof lamp:1pc power:100w l Conveying device:Chain reciprocating l Air compressor:1set power:7.5kw l Dust control of axial flow fan:1set power: 200w

l Agitator: 1set power:1.5kw

Equipment production environment configuration: 1 equipment linear arrangement : the length of the workshop is not less than 80 meters, the width of not less than 15 meters, 2 equipment turning arrangement : length of the workshop is not less than 40 meters, the width of not less than 15 meters.

2. Auto stone coated section l Appearance size:3500×1000×1500mm l Framework: Steel welding l Conveying device:Chain reciprocating l Automatic sand hopper: 1set capability:200kg l Bucket lift:1 set l Manual sandblast gun:4sets

3. The first time drying section l Appearance size:25000×1000×1200 mm l Framework: Steel welding l Frame type thermal insulation wall: 1.2mm cold steel with Rock wool l Automatic temperature controller:4set Range:0°~160° l Infrared heating tube: 30pcs Power:30kw l Conveying device:Chain reciprocating l Air cooling device:1 set Power:200w 4. Auto face glue spraying section l Appearance size:3000×1000×2000 mm l Framework: Steel welding l Damp proof lamp:1pc Power:100w l Automatic pressure spray tank:1set capability:200kg Range:0.6~1Mpa l Conveying device:Chain reciprocating l Automatic spray gun:4 set(spare parts) l Manual patch glue gun:4 set l Dust control of axial flow fan:1set power: 200w l Automatic glue machine motor: Servo motor, Power:750w 5. The second time drying section l Appearance size:30000×1000×1200 mm l Framework: Steel welding l Frame type thermal insulation wall: 1.2mm cold steel with Rock wool

Pictures of machine:

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period.

2. Effective communication

3. Interface customized.

Looking for ideal Coated Roof Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Colorful Stone Coated Machine are quality guaranteed. We are China Origin Factory of Stone Coated Production Line. If you have any question, please feel free to contact us.

Product Categories : Stone Coated Roof Tile Production Line

Product detail pictures:

Related Product Guide:

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for Best Price on Steel Frame Roll Forming Machine - stone coated roofing tile production line – Yingyee, The product will supply to all over the world, such as: Finland, Slovenia, Doha, With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!